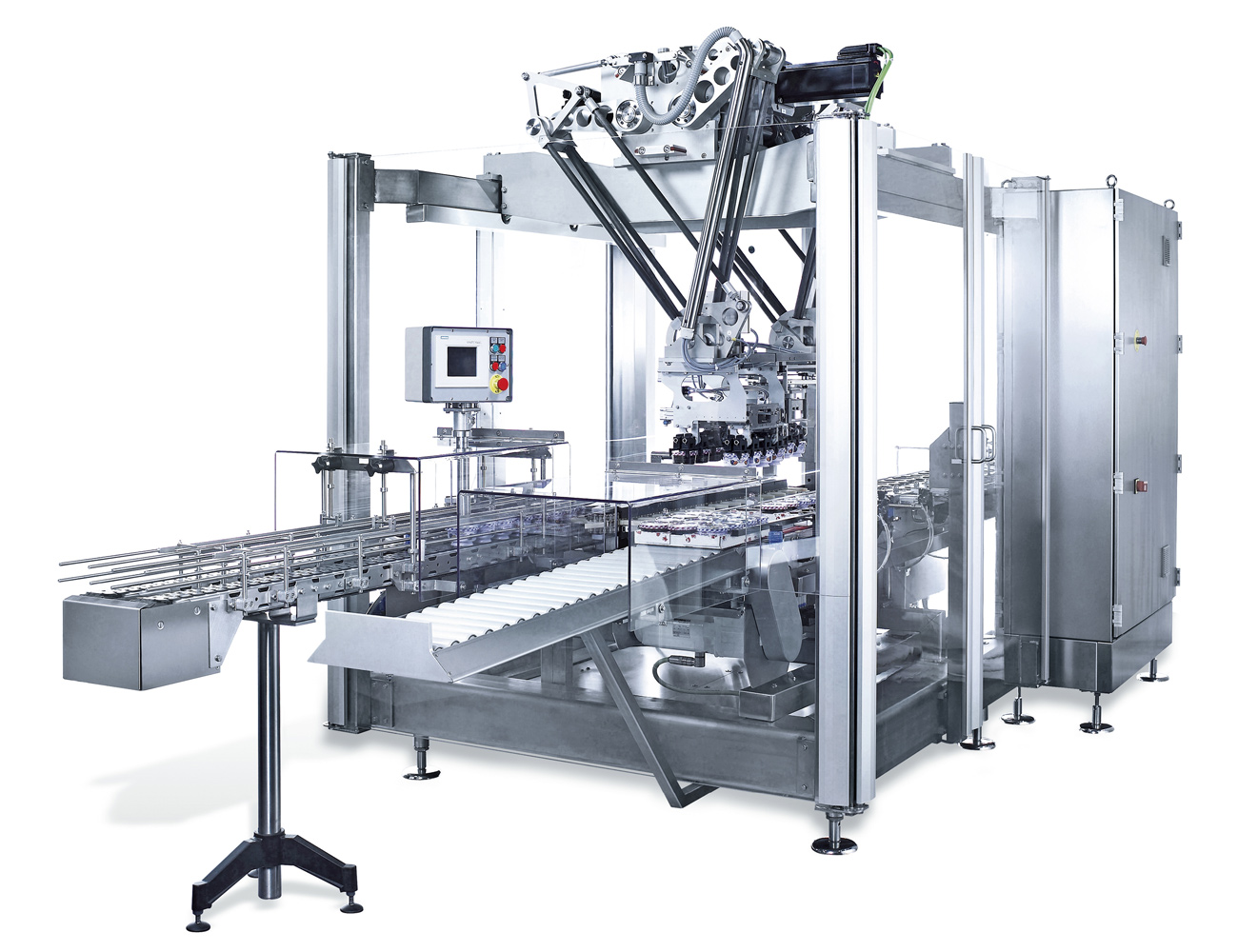

Pick+Place Packer

TwinLine

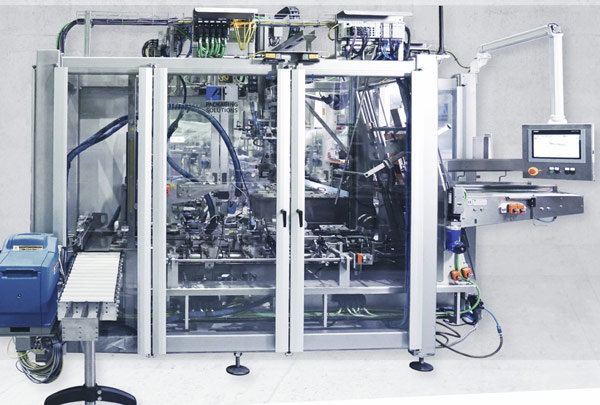

Create a multifunctional basic module for a variety of packaging tasks. You are looking for an all-rounder with the ideal mix of speed and load capacity? Then the twin-axis robot A+F TwinLine offers you the perfect basis for any application in the packaging industry. The module can be adapted to your specific task at any time by means of servo-pushers, suction grippers or mechanical grippers and also using additional turning and tilting functions. Use the easy-to-operate A+F TwinLine optionally for collation of the primary products, for sorting cups or beverage bottles or for a different pick-and-place task.

By the way: Thanks to drive struts made of lightweight CFRP and the installed servo technology, fast reactions and short cycles with loads of up to 63 kg can be realised without difficulty.

A+F TwinLine in detail

Benefits

- Unique combination of short reaction time, fast motion sequences and high payload up to 63kg with a high positioning accuracy

- Innovative technology in lightweight construction and servo technology

- Application- and customer-specific designs of the product infeed and the carton line as well as application-specific design with servo-driven pusher, suction gripper or mechanical gripper

- Multiple uses - pre-grouping of primary products, repacking or sorting of products as well as insertion of products into product carriers, trays or perforated trays

- Low production costs due to high-quality, low-maintenance design

- Ergonomic design for optimum operability and fast format changeover in less than 10 minutes

Technical details

- Control:

TwinLine MIN: Schneider Electric, Allen Bradley

TwinLine ST: Schneider Electric, Allen Bradley

TwinLine MAX: Schneider Electric, Allen Bradley - Weight capacity:

TwinLine MIN: 10 kg

TwinLine ST: 25 kg

TwinLine MAX: 63 kg - Reach A:

TwinLine MIN: 630 x 320 mm

TwinLine ST: 1080 x 400 mm

TwinLine MAX: 1350 x 500 mm - Range B:

TwinLine MIN: 500 x 254 mm

TwinLine ST: 800 x 400 mm

TwinLine MAX: 1070 x 500 mm

Applications

- Grouping, handling and aligning products

- Sorting products, e.g. cups or bottles

- Positioning products in product carriers or loading products into secondary or tertiary packaging

- Containers: pre-formed boxes, open trays, perforated trays, trays with lids.

Options

- Exchange tools for quick format change

- Connection of the TwinLine to upstream and downstream equipment in an extremely compact configuration

- Customised and application-specific configurations and technical solutions

- Optional integration of an optical detection system for product position and orientation detection

- Systems for detecting product contamination and rejection in terms of integrated quality assurance

- Intelligent palletising solutions

Select your language