From two to four production lines

Bremen-based saturn petcare GmbH expands in the USA – with palletizers from Germany

There is an attractive market for pet food, especially for wet food for dogs and cats. Clear evidence of this comes from Bremen-based saturn petcare GmbH which has doubled its production lines in the USA from two to four lines. The palletising system was brought over from Germany. Performance, flexibility and excellent experience gathered in practice played a decisive role for this decision.

The global pet food segment has shown significant growth in recent years. According to market researchers from the online platform statista, sales are likely to reach around 140 billion euro in 2024. They even expect the market to grow by more than five percent per annum up to 2028.

Drivers of this trend are, among others, demographic change, the increase in the number of single-person households and the significant rise in available income. The “humanisation of pets“ is cited as another factor. High-quality raw materials, natural ingredients and superfoods are currently very much in demand for pets as well. And last but not least, the number of pets simply increased during the COVID-19 pandemic.

The order comprised the necessary conveyors including spiral conveyors, the integration of the two palletisers, automation and clarification of the interfaces as well as commissioning including operator training.

The order comprised the necessary conveyors including spiral conveyors, the integration of the two palletisers, automation and clarification of the interfaces as well as commissioning including operator training.

Since 2021 practically the same plant operating in Bremen

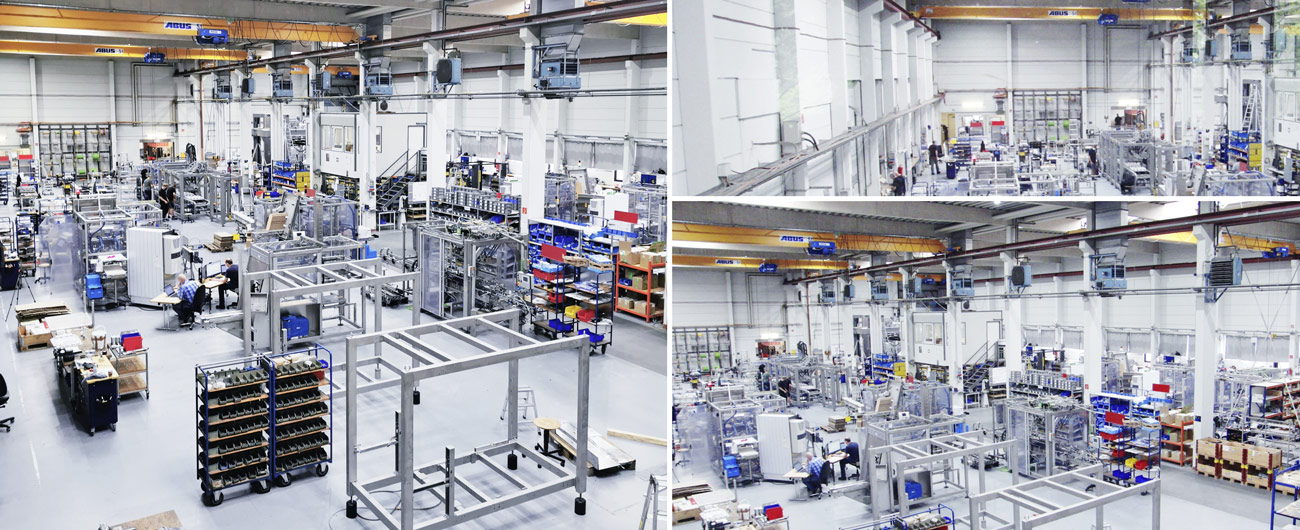

saturn petcare GmbH, which is part of the Heristo Group, is a company that is extremely successful in this field on an international scale. Its production facility at the company’s headquarters in Bremen was built in 1991. From then on, they have been producing wet food for dogs and cats for retail trade on state-of-the-art production lines at this site. Customers are mostly food chains that sell saturn products as their own brands. The production facility is IFS-certified and therefore meets the highest standards in terms of quality and product safety. With documented success: The Stiftung Warentest foundation took a close look at cat food in 2020. The result: six of the best 8 products came from saturn petcare, in 2024 even 4 out of 5.

Besides its works in Germany, saturn petcare has production sites in the Netherlands and, since 2021, also in the United States, which is currently the strongest-selling market worldwide. Within the framework of this expansion, a state-of-the-art production plant for wet food was realised at the site in Terre Haute in the federal state of Indiana, which was upgraded from two to four production lines in 2023. The plan was to replicate the systems one-to-one. This was also implemented – with the exception of the two palletisers. Harald Knaup, project manager at saturn petcare in Bremen, Germany, looks back: “The reason for this decision was the concept of the palletising system, the design structure, the additional add-ons such as Condition Monitoring, layer pattern generator or the maintenance manager, the attractive price-performance ratio and, last but not least, the good experience we have had with the practically identical plant here in Bremen since 2021.“ According to Knaup, another plus point was the layer pad inserter, which can be loaded with new material without the palletiser stopping.

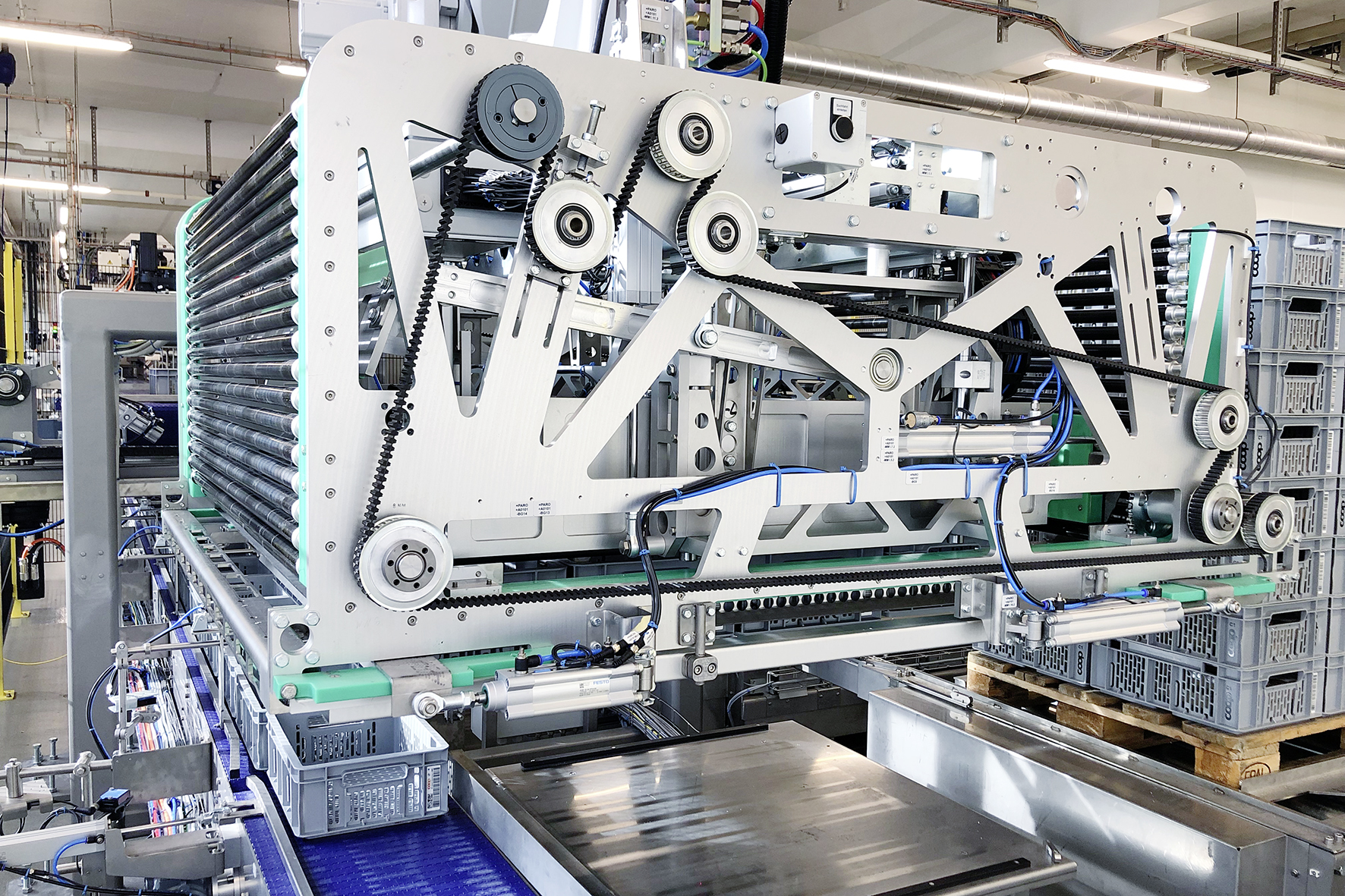

The palletisers work according to the ‘lifting pallet’ principle. They are able to process very high loads and achieve an output of up to 280 layers per hour.

The palletisers work according to the ‘lifting pallet’ principle. They are able to process very high loads and achieve an output of up to 280 layers per hour.

Conversion “at the press of a button”

Both the palletiser in Bremen and the two in the USA operate according to the “lifting pallet” principle. They are able to process very high loads and reach an output of up to 280 layers per hour. Due to the extensive use of servomotors and the omission of pneumatics, the machines carry out the palletising work in a highly energy efficient manner. With the “layer pattern generator” they are also highly flexible, as in this case the desired layer patterns are stored. All it takes is a “push of a button” to change them. The tool also supports the optimisation or design of a layer pattern.

Understandably, when comparing Bremen and the United States, some country-specific modifications were needed. For example, the US standards had to be verified and the operating language and pallet format had to be adapted. The 120-volt power supply in the US is also different. For this purpose, a corresponding transformer was installed in Germany in order to be able to test the electrical system and the control in advance. And talking about control: “For America, it was unusual that we had installed the Siemens S7 controller. This was an issue to begin with, but now they are extremely satisfied”, Knaup adds.

All in all, eight 40-foot containers shipped

The physical transport was another factor: the plant was split into as large parts as possible and stored in eight 40ft containers. The final container was loaded on a ship for New York on 22.08.2023. From there it was transported over 1,000 km on heavy-duty trucks to Terre Haute, where assembly began on 16.09.2023. The construction site was managed by a supervisor for mechanics, a supervisor for electrics and a commissioner. These were supported by five mechanics and three electricians from saturn petcare. In future, the plant will be looked after by the US company Standard-Knapp and from Germany via the internet. “A clear signal underscoring the international competence and expertise of the EOL Group”, Knaup emphasises.

Modern communication as an important tool

In concrete terms, the order comprised the required conveyor systems including spiral conveyors, the integration of the two palletisers, the automation and clarification of the interfaces as well as the commissioning including operator training. This complete package was executed on a turnkey basis. Modern, state-of-the-art communication and construction site management with LOP 4.0 were essential tools in this transatlantic collaboration project.

LOP 4.0 is a cloud-based system to which all parties involved in the project have access. This digital platform maps the project status with the highest possible transparency during the construction site phase, from the delivery right up to commissioning. LOP 4.0 is furthermore an open communication and documentation platform. Each project partner can, for example, upload photos or videos, propose next steps for discussion or prioritise individual items. This makes sure that the presentation of the status of all project modules is always up-to-date and clearly understandable. Any interactions with the next steps can thus be seen immediately. This reduces conflict and coordination losses and leads to a high level of planning ability.

Maximum flexibility: the palletisers either handle two products in parallel or each the same product, or only one of the two is in operation.

Maximum flexibility: the palletisers either handle two products in parallel or each the same product, or only one of the two is in operation.

“A truly harmonious and focused collaboration“

Acceptance took place on 31.10.2023. “It was a truly harmonious and well-focused collaboration”, saturn petcare sums up. During the everyday production the two palletisers now each pick up two carton formats from the upstream filling and packing systems, in which different types of pet food are packaged. In the infeed area of the palletisers the infed cartons are turned and positioned according to the desired layer formation. This creates layer patterns that are individually adaptable by the customer. The pallets stacked in the palletiser are then conveyed to the discharge point via the pallet conveyor and from there they are conveyed to the warehouse. The pallets, in turn, are automatically fed in via a magazine. The two palletisers run both products in parallel or the same product, or just one of the two is in operation. The palletisers therefore not only boast high performance and reliability, they are also very flexible in use, and that means a really reassuring outlook considering the forecast growth scenarios.

Compact, flexible, powerful

Emmi AG, Switzerland, invests in a state-of-the-art packing and palletising solution for thermoforming trays

Raclette does, of course, have a definite peak season. But there is also a stable demand beyond the cold time of the year. So stable, in fact, that the Swiss Emmi Group invested in a state-of-the-art raclette cheese slicing plant last year. Key components are a combi-packer for wrap-around cases and plastic crates and a multifunctional robot palletiser.

Switzerland, dairy, Emmi – that’s rather like taking owls to Athens. Emmi is Switzerland’s largest milk processor with a strong international presence, well ahead of its competitors. In 2023 the Emmi Group generated sales of CHF 4.232 billion, slightly higher by 0.3 percent than in the previous record year of 2022. Organic growth amounted to 3.5%. Strategically important markets such as the USA, Brazil and Chile as well as Switzerland have been particularly successful.

The case packer inserts the thermoformed trays into wrap-around cartons (left) and two returnable plastic containers (right).

The case packer inserts the thermoformed trays into wrap-around cartons (left) and two returnable plastic containers (right).

Also very popular for cheese burgers

In this connection, a significant role is played by the cheese segment, including the famous raclette cheese. But isn't raclette synonymous with cold, snow and Christmas? Not at all, explains Martin Küttel, the responsible value stream manager at Emmi: "Demand is, of course, about three times higher in the cold months. But there is also a stable demand for raclette during other times of the year. The cheese is very popular in cheese burgers, for instance." Emmi therefore decided to discontinue two existing raclette slicing lines and build a completely new line at the Emmen site. With clearly defined investment goals. "First of all, we wanted a significantly higher output. Our second objective was to implement automation. Previously, this was only the case with carton packaging. We processed the returnable packs, typical for Switzerland, manually, this also being the case for the entire palletizing process," Küttel explains.

Wrap-around as an attractive alternative

There were three decisive reasons in favour of the solution implemented in 2023, Küttel points out: “What we actually wanted was a two-part carton again. But then we had the option of the wrap-around, which saves us money.“ The second main reason, according to Küttel, was that Emmi can now process both the carton as well as the reusable pack on just one machine. “All other suppliers would have required two machines for this, which in turn would have taken up more space, among other things.“ And thirdly: „Our current palletiser performs all the tasks with just one single gripper head. Other suppliers would have needed twice as many.“ Küttel adds.

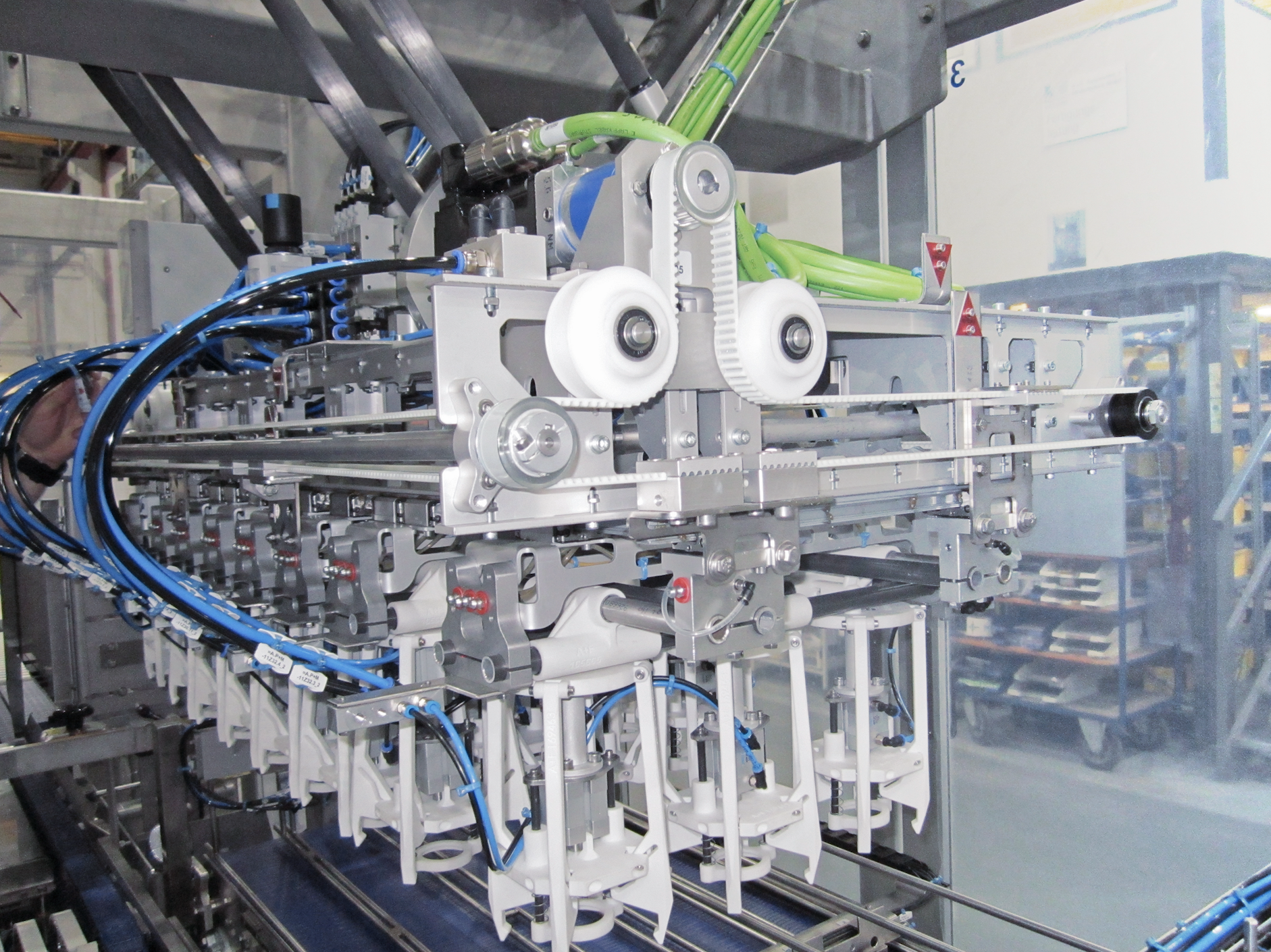

New design made up of proven modules

The order was for a ModuLine case packer for thermoforming trays in wrap-around cases and two returnable plastic packs. This packer is a new design based on existing and proven machine modules – it is currently a unique model. The order also included a robot palletiser and depalletiser for returnable packs, wrap-around cases as well as layer pads, the necessary conveyors for returnable packs, wrap-arounds and pallets as well as a turntable stretch wrapper and a pallet labeller. The entire project was completed on a turnkey basis.

All palletising and depalletising tasks, including the application of intermediate layers, are performed by just one gripper head.

All palletising and depalletising tasks, including the application of intermediate layers, are performed by just one gripper head.

The pack and palletising unit was approved in December 2023. It has been performing well since then in everyday use for the following processes: The aligned thermoforming trays are taken from the customer’s conveyor in one lane with the short side leading and the decor on top, and are then conveyed into a cavity where they are stacked. Six cavities are attached by means of quick-release fasteners to a cell chain arranged in a square with two pulls. Once the cavities have been filled, they are cycled to the 2-axis portal where they are then lifted. The 2-axis portal lifts the stack using a gripper and, depending on the programme selection, places the stack in the tray that has been pre-folded from the flat blank, or in one of the two returnable packs. It is important in this process that the length and width packing parameters do not change.

Grammage defines the height of the packaging

The packaging height, on the other hand, is variable depending on the desired grammage. Küttel explains: "The tray as packaging type is a very volatile market. New grammage was already requested during the course of the project.“ This entailed substantial programming work in order to ensure the required flexibility for the packer. With success: “We can now make the necessary adjustments here on the machine“, Küttel adds.

The trays are then glued around the product using hot melt and then discharged to the side. The filled returnable packs are also conveyed to the palletising area via conveyors. Maximum energy efficiency was ensured in all areas by a closed loop servo drive system in the axis arrangement, for example, or by lowering the temperature of the gluing unit when not in use.

The wrap-around solution replaces a two-part carton: ‘This saves us costs.’

The wrap-around solution replaces a two-part carton: ‘This saves us costs.’

Accomplished with a single palletising head

In the robot palletising cell, both the empty returnable packs are depalletised from the carrier pallets and fed to the packer and also the full returnable packs and wrap-around cases coming from the packer are palletised and the layer pads inserted. This is all accomplished with a single palletising head. “We have three different types of secondary packaging, two different pallet types as well as a layer pad for the cases. And with a limited amount of space. The robot saves space and, with its multifunctional gripper head, it is much more flexible than other palletising cells“, Küttel explains.

The palletising cell was integrated in the overlying ERP system. This sends the required data for the respective palletising order to the robot, which automatically adjusts to it. The palletising is thus controlled by the ERP system. The same applies to the application of the required pallet label. Manual acquisition of data at the palletiser is not required. Another software tool is the Condition Monitoring. This programme creates statistics, documents any system errors and allows a system analysis via the internet.

The robot palletiser also feeds the returnable packs to the packer.

The robot palletiser also feeds the returnable packs to the packer.

„We are now really well positioned“

“We remain calm and relaxed as we look ahead to the next peak season. We are really well positioned with our new raclette line“, Küttel sums up. An important tool in this successful project handling was the construction site management system LOP 4.0. LOP 4.0 is a cloud-based system to which all parties involved in the project have access. This digital platform maps the project status with the highest possible transparency during the construction site phase, from the delivery right up to commissioning. LOP 4.0 is furthermore an open communication and documentation platform. Each project partner can, for example, upload photos or videos, propose next steps for discussion or prioritise individual items. This makes sure that the presentation of the status of all project modules is always up-to-date and clearly understandable. Any interactions with the next steps can thus be seen immediately. This reduces conflict and coordination losses and leads to a high level of planning ability – and customer satisfaction. And as they say: only a satisfied customer is going to place the next order. This was obviously the case for Emmi – the order for another packer and case erector has already been placed with the EOL Group.

Handling cups, trays and cases

Wernsing Feinkost invests in an innovative packing unit - for packing, erecting and stacking

At Wernsing Feinkost GmbH a new plant was put into operation last year which fully automatically places cup-filled products into cases or trays. This solution combines the actual packer with a carton erector and a stacking unit. This compact packing unit has been integrated into an existing line and has a rated output of 150 cups per hour. Read on for a portrait of the company.

The history of Wernsing goes back to 1962, in Addrup-Essen/Oldenburg, in the state of Lower Saxony, when a production facility for French fries was founded. Heinrich Wernsing, then 28, laid the foundation for an exceptional success story. Over the years this small family business has become a modern and dynamic company which is still held in sole proprietorship.

The new packing cell at Wernsing Feinkost GmbH has a rated output of 150 cups per hour.

The new packing cell at Wernsing Feinkost GmbH has a rated output of 150 cups per hour.

Annual sales of over one billion euros

Today, Wernsing Feinkost GmbH is part of the Wernsing Food Family that generates annual sales of over one billion euros at eight production sites in Germany, and at other facilities in Belgium, Denmark, the Netherlands, Poland, Sweden and Spain. In total, this European family of companies employs more than 4,000 people. The site at Addrup alone has more than 1,150 employees, making Wernsing Feinkost GmbH one of the most important employers in the region.

The company group boasts a wide range of products and continues to grow steadily. The portfolio covers potato products as well as antipasti products, spreads, desserts, dressings, dips and sauces, marinades, pasta and savoury products, salads and also soups and stews. In addition to this product range, the services offered by Wernsing, such as the development of individual recipes or repacking, are also much in demand by wholesalers, food retailers and discounters, as well as industrial partners in Germany, in many European countries and around the world.

The cup packer is based on the proven Twin-Line basic design, which is individually adapted to each customer's specific requirements.

The cup packer is based on the proven Twin-Line basic design, which is individually adapted to each customer's specific requirements.

Challenging plant layout

In order to be able to keep up with this high level of diversity and the constant growth on the production and packaging side Wernsing is committed to ongoing investments in state-of-the-art plant technology. This is where, for more than two decades now, A+F Automation + Fördertechnik GmbH has been a key partner. The last joint project was in 2021 when an A+F cup packer system was replaced at the Addrup site. The need to invest in a replacement was due to the advanced age of the system and the planned expansion in the production to include yet another packing concept. The corresponding adaptation of several line components also led to an increase in the hourly output.

The gripper fingers were made of plastic using 3D printing. This process offers many advantages compared to milling out the fingers.

The gripper fingers were made of plastic using 3D printing. This process offers many advantages compared to milling out the fingers.

The contract was awarded in August 2020. In detail, the project comprised the plant layout, the packing unit as well as the necessary conveyors and buffer sections. The job was carried out on a turnkey basis. Wernsing was responsible for on-site work by others, such as the dismantling of the old plant, for example. The design of the optimal plant layout proved to be a particularly challenging task. This was due to the very limited available space which was restricted further by numerous existing columns. In addition to this, strict adherence to the interfaces specified by Wernsing was required, and on top of this, Covid-19 measures such as the wearing of masks, keeping a distance, disinfection and testing had to be observed as well.

Gripper fingers produced by the 3-D printer

For the machine, Wernsing decided in favour of the innovative Twin-Line Cup Packer. This is based on a proven basic design that is individually adapted to the customer’s specific requirements. Basically, the Twin-Line packer is a packing unit with two conveyor streams. The one conveyor infeeds a case, carton or tray. The second conveyor is for the infeed of the product. Both streams can be designed to run parallel, but they can also run in opposing directions, feature a single-lane or a multi-lane design. Another option is to use a bar chain. The incoming cups are then picked up according to the packing pattern and placed in the carton.

The bucket packer was combined with a tray erector in the infeed.

The bucket packer was combined with a tray erector in the infeed.

The pick-and-place system is always individually adapted to the product. At Wernsing, the product is grabbed, for example, and not sucked up. The required mechanical grippers for this purpose comprise a rectangular plate with four mobile fingers positioned at the corners. These fingers have to feature a geometry that exactly matches the cup to be picked up. To this end, the fingers are made of plastic using the 3-D printer process. This is much more accurate than cutting out the fingers in a milling process. The plastic material for this purpose is also extremely durable and boasts minimal wear.

The gripper is moved by a so-called handling module that is driven by servomotors. In this way, the mounting plate for the respective grippers can always be positioned precisely by the control system. Wernsing uses two different types of grippers for the required pack formats. These can be replaced by means of quick-release couplings, thus ensuring fast format changes. In addition, special format part carriages make it possible to keep all relevant parts neatly arranged near the respective machine.

2 x 3 or 3 x 3 cups either in single or double layers

For Wernsing, the Twin-Line Packer was combined with a carton erector in the infeed and a stacking unit in the outfeed. In addition, a labeller provided by the customer was also integrated in the infeed. All components were delivered as from 27.02.2021, these were then set up and electrically connected by 03.03.21. The commissioning began on 02.03. The acceptance took place on 12.03.21 already. During the actual packing process the cups are fed in on the customer’s side in a single lane. The Twin-Line Packer also takes up the cups in a single lane and then, depending on the pack format, distributes the cups over three or four lanes in the infeed. The actual pack formats for the plant are 2 x 3 or 3 x 3 cups, either in a single layer or in a double layer. The previously erected cases or trays reach the packing plant at the same time via the second conveyor belt. Once positioned under the handling module with the appropriate gripper, the module inserts the cups assembled to the selected pack format. With the pack format 2 x 3 always two cartons are filled at the same time in order to achieve the required output per hour. In this case, the infeed of the cups is on four lanes. The pack format 3 x 3, on the other hand, is formed on three lanes. The filled packs then move into the stacking unit. Here stacks of packs are formed depending on the palletising pattern of the customer’s loader. Stacks with two or three layers are possible. The case or the tray can, however, also be fed directly to the final palletising system. The achievable rated outputs are listed in Table 1. The packer itself is designed for a rated output of 150 cups per minute.

Condition Monitoring as a useful tool

All plant components are designed to allow a smooth subsequent conversion or expansion within the given structural limits. For example, Wernsing also offers a cup with a lid size of 130 x 130 mm, that can be processed by the Twin-Line Packer at a later date, as required. To put this in perspective: the size of the cups is currently approx. 114 x 114 mm. And speaking of the future: In this connection, Wernsing also decided in favour of using the Condition Monitoring tool. Condition Monitoring is used to automatically record extensive data relating to the production, machine and the environment. This applies, among other things to status messages, warnings and malfunctions of the machine as well as production data. All of these data are stored on a stand-alone industrial PC, archived and displayed on a dashboard that can be accessed using any up-to-date browser. The architecture can thus be integrated in a company network without requiring additional hardware. This tool is particularly interesting for maintenance purposes as any required measures, such as the replacement of a bearing, can be detected in advance, as a preventive measure. Through the achieved transparency it also offers Wernsing the opportunity to optimise and secure the plant’s performance. In short: output, flexibility and reliability are three absolute key factors behind the Wernsing success model, and these are realised 100 percent with the new Twin-Line solution, also with a view to the future.

Read the full article as an online pdf. Published in LVT Lebensmittel Industrie, copy 5-6/2022.

Cardboard instead of plastic

The British company, Premier Foods, accomplishes an innovative packaging and palletising solution for dessert cups

No longer wanting to sell its dessert cups in shrink-wrapped plastic trays, the British company, Premier Foods, decided to invest in a combined packaging and palletising centre. Here the cups are now packed in cardboard cases using tray erectors and sleeving machines and then palletised fully automatically. The palletising centre simultaneously handles two additional packaging lines. The entire plant was successfully approved in February 2022. Read on for a more detailed portrait.

As one of the largest listed food companies in the UK, Premier Foods employs a workforce of over 4,000 people at 15 production sites and different branches across the UK. Some 96 percent of the products are made in the UK. The raw materials are supplied to the maximum possible extent by British merchants and farmers.

In the used palletisers the changeover of pallet type takes place via stored product settings. This is also the case with the layer pattern.

In the used palletisers the changeover of pallet type takes place via stored product settings. This is also the case with the layer pattern.

Rice pudding, other puddings and desserts

The brand portfolio of Premier Foods is divided into four main categories, these being: flavours and seasonings; sauces and accompaniments; convenience foods, snacks and soups; and lastly aseptically packaged desserts. In addition, the corporate group makes products such as cakes and desserts to order for many food retailers in the UK.

At the Ambrosia Creamery, Premier Foods makes the UK’s most popular rice pudding and pudding desserts, as well as a host of other desserts. The company itself dates back to 1917. The production site is located in the village of Lifton, in the heart of the county of Devon in southwest England.

Goal was a state-of-the-art multipack format

The first packaging line from A+F went into operation at the Lifton site back in 2012. Since then, a number of other projects have been completed in joint cooperation, the last of which was at the beginning of 2022. “The most recent collaboration was for the development of a state-of-the-art multipack format for our popular dessert cups. In this project we wanted to simultaneously change over to a more sustainable case solution,” comments Graeme Strike, project manager at Ambrosia. At that time, the filled cups were being inserted into an open plastic tray that was additionally wrapped in shrink film prior to palletising. “Now we pack our cups in solid cardboard sleeves and corrugated cardboard cases,” Strike adds.

In addition to this challenge, a suitable plant layout had to be determined in order to be able to spatially incorporate the planned palletising centre with integrated packaging unit in the respective hall intended for this purpose. Furthermore, all existing options from cup filler to product routing were to be maintained. This is where flexibility in the packaging unit design, with its tray erector and sleeving machine, was hugely important. Because this would ensure that the cups could leave the filling line in the existing format and still be processed in a seamless manner by the new packaging and palletising line“, Strike explains.

Successful award of contract after an extensive tendering process

The first stage in choosing a machine was an elaborate tender process. Strike recalls: “It was here that the tray erector and sleeving machine stood out from the rest as well-established and proven flexible machines.“ And there was a further additional advantage over the competitors: the existing equipment could be adapted to the new conditions without any difficulty whatsoever. Choosing one of the other bidders would have necessitated an investment by Premier Foods in replacements. “So the final decision was relatively easy for us”, Graeme Strike continues.

The SetLine sleeves up to 304 dessert cups per minute.

The SetLine sleeves up to 304 dessert cups per minute.

The contract included the layout, two new palletisers, the conversion of an existing palletiser, a multi-former tray erector and a SetLine sleeving machine, also all required conveyors as well as the mechanical-side and control-side connection to the specified interfaces. Two spiral conveyors were purchased and integrated by the general contractor. Equipment from third parties was also taken over, such as X-ray-checkweighers, Inkjet printers, pallet wrappers as well as pallet and case labellers.

During the plant planning, particular attention was paid to ensuring the most energy-efficient operation possible – one of the goals being to minimise the use of expensive pneumatics. Consequently, the most up-to-date servo drives and three-phase drives are used, and vacuum pumps replace conventional Venturi vacuum generators. The entire project was managed on a turnkey basis, including the dismantling and training of operating staff.

Specified output reached in record-breaking time

Assembly work in Lifton started at the end of 2021. The new packaging and palletising centre reached the specified output in record-breaking time. Acceptance was successfully completed in February 2022, just a few weeks after the commissioning. “This was also made possible thanks to the excellent operator training”, Strike emphasises. Another useful tool in this respect was, of course, the “digital twin”. This system is used in the run-up to an investment to determine via computer simulation how to best implement the task set by the customer in a technically and economically expedient manner. In the Premier Foods project this focused on the design of the pallet transport system. However, the “digital twin” can do a lot more than just computer simulation. The tool runs the exact PLC that is to be used by the customer, and this in turn controls the simulation. The knowledge gained in these tests, that are run under close-on operation conditions, helps optimise the machine design as well as the subsequent commissioning at the customer’s premises.

The tray erector, type MultiFormer, automatically forms the desired packs comprising sleeve and wraparound tray.

The tray erector, type MultiFormer, automatically forms the desired packs comprising sleeve and wraparound tray.

Designed for 24/7/365

Since then, the packaging and palletising centre has proven its worth under tough day-to-day working conditions. The plant is designed for 24/7/365. It is currently being used in a two-shift operation. The sleeving machine forms the packaging variants: 2 cups x 1 layer = 2 cups, 2 cups x 2 layers = 4 cups as well as 3 cups x 2 layers = 6 cups. The rated output is 304 cups per minute. The tray erector subsequently forms the desired packs comprising sleeve and wraparound tray. Its rated output is 19.0 packs per minute for the 2-cup sleeves and 12.7 packs per minute for the 3-cup sleeves. The palletiser of the new packaging system also has a rated output of 19.0 packs per minute. The other two palletisers simultaneously handle two other packaging lines. Their rated output is 13.9 packs per minute respectively. On all three palletisers Chep or Euro pallets are used. The changeover of pallet types is carried out - as with the layer pattern changeover - using stored product settings.

“Something we can all be proud of“

“We were well aware of the company’s potential and that of its components“, says Strike. This was an important aspect, considering that the general conditions were far more challenging this time - the project had to be carried out under the difficult circumstances of the UK having left the EU and the Covid pandemic. Among other things, the installation teams had to go into quarantine. Summing things up Strike concludes: “Despite these unprecedented challenges, the A+F team were always closely engaged with us and extremely cooperative. This was definitely one of the key drivers in getting the project done within the budget and on time. And that is something we can all be proud of.”

Tricky conditions: an inclined area, fluctuating dimensions, irregular orientation

The Sachsenmilch dairy automates its cheese wedge packaging using a Flexpicker

Sachsenmilch Leppersdorf GmbH is one of Europe’s most modern dairies and one of the largest investment projects in the history of the Theo Müller Group. Over one billion euro has been invested in the new development and in expansion projects since the takeover. A further investment was successfully concluded at the beginning of 2021. The goal was to automate the previously manual packing of cheese wedges.

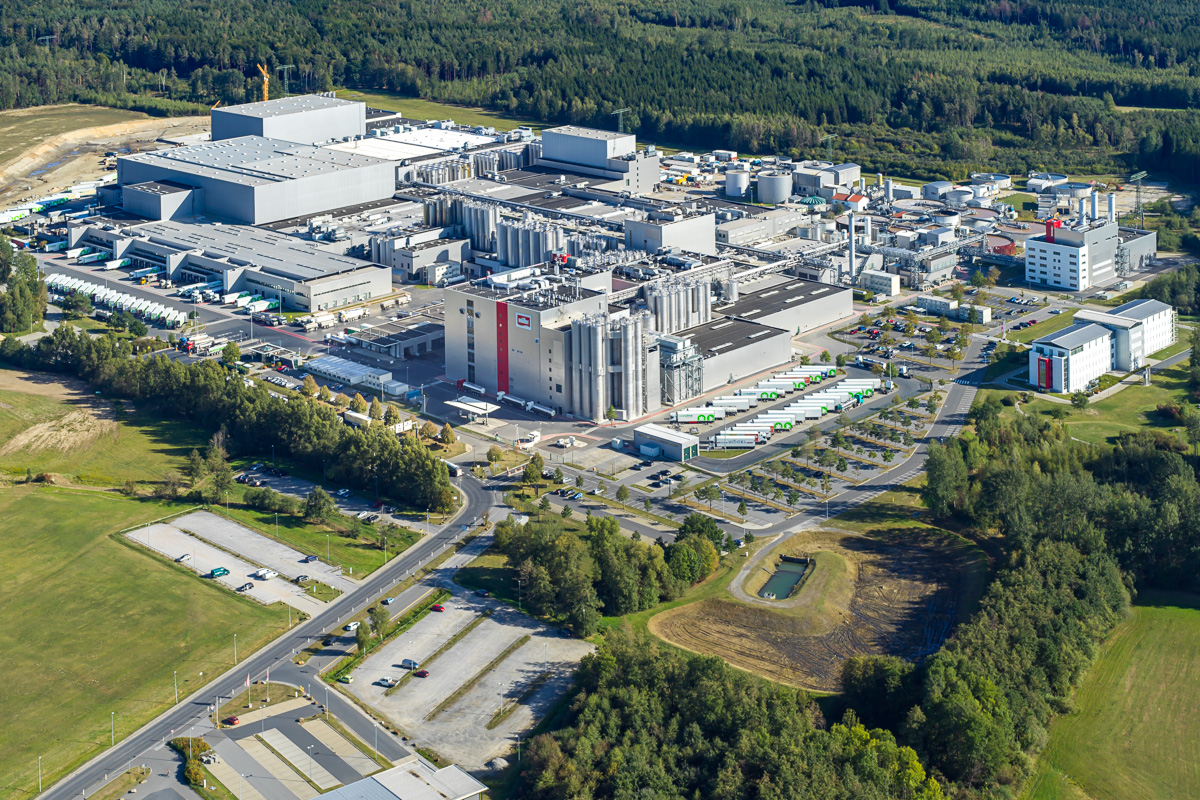

With some 2,800 employees Sachsenmilch processes around 1.8 billion kilogrammes of raw milk a year into a wide range of products that, besides milk, butter, yogurt and cheese, also includes whey derivatives for baby food as well as bioethanol. The food products are sold under the brand names Sachsenmilch, Müller und Loose, among others.

An impressive sight: with some 2,800 employees Sachsenmilch processes around 1.8 billion kilogrammes of raw milk a year into a wide range of products.

An impressive sight: with some 2,800 employees Sachsenmilch processes around 1.8 billion kilogrammes of raw milk a year into a wide range of products.

Cheese wedges vary in size significantly

About half of the raw milk supplied is processed into cheese and packed in packaging variants to meet the customer demand. Sachsenmilch’s 450 g cheese wedges, which are machine cut from cheese wheels of approx. 12 kg according to a defined pattern, play an important role in this process. The square-shaped middle cut which produces three wedges, is always identical. These sections can always be identified in that they only feature two sides of rind and not three, as is the case in the wedges cut from the edge. The size of the middle wedge is always the same, whereas that of the outer wedges varies significantly. The reason for this is as follows: although all cheese wheels have approximately the same weight, they vary in diameter and height due to the maturing process. If the diameter of the wheel is smaller, for instance, then the edge wedge is shorter and wider, whereas with a larger diameter the segment is longer and thinner.

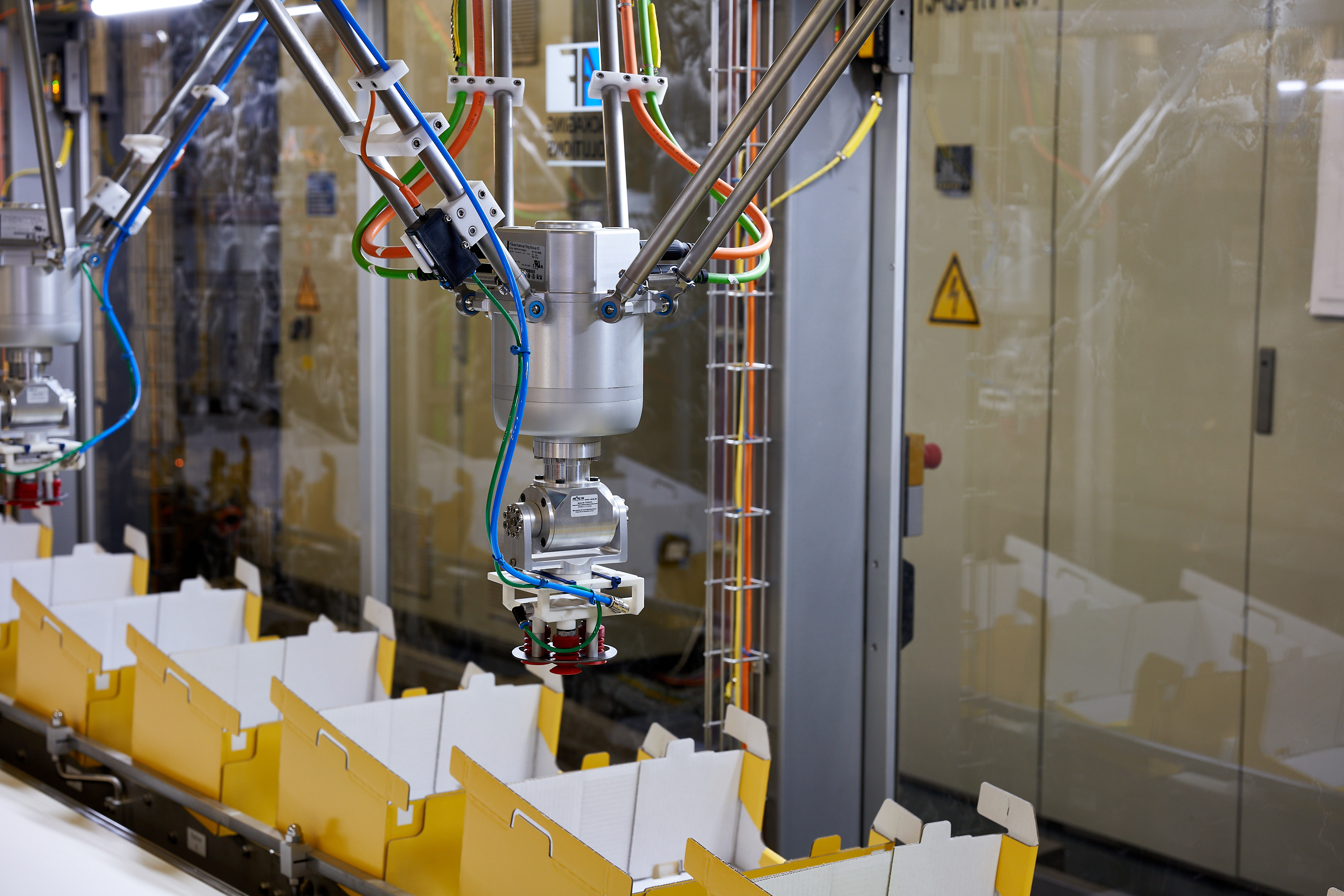

The compact and high-performance Flexpicker with integrated cartoner

At Sachsenmilch the cheese wedges have until now been put into shipping cartons manually. “This type of work has great potential for automation. We were therefore looking for a solution that would enable an efficient mechanical packing of the cheese wedges,“ recalls Katharina Rossow, Project Engineer for Technical Projects at Sachsenmilch. During the initial planning phase, it was even considered changing the entire cheese wedge production to mechanical processing. “The packer, however, would then be so big that it would exceed the available space at the planned site”, Rossow comments. Sachsenmilch therefore focused on the main cheese type that accounts for approximately two-thirds of the production. The remaining third was to continue with manual insertion into the trays.

“We decided in favour of a cooperation with A+F due to their sound and reliable technology and the positive experience from many joint projects especially regarding the individual customised solution and project implementation “, Rossow points out. The key element of the solution is a so-called Flexpicker with integrated cartoner. This Flexline design combines two proven product groups in one machine frame, both mechanically and regarding the control. The result is first of all a significant synergy effect in the control – one system is all that is needed for both tasks. Secondly, the machine boasts a very compact design which is another bonus, and not just for Sachsenmilch. This is because with existing buildings there is always the challenge of finding a machine that fits into the available space conditions. Rossow emphasises: “This worked out perfectly. Operation and maintenance of the plant can be carried out easily from all sides. The solution simply meets all the requirements originally set out by Sachsenmilch.“

Gripper system, sensor system and condition monitoring make their debut

Unlike the components of the basic machine, the sensor system and the gripper system for the cheese wedge product had to be developed from scratch. “At Sachsenmilch we were not familiar with the chosen technology, but it quickly became our preferred solution. And we were confident that it would do the job”, Rossow adds.

The condition monitoring module also made its debut at Sachsenmilch with this project and was integrated in the Flexline packaging machine. Condition monitoring automatically records comprehensive data on the production, machinery and surrounding area. This also applies to status messages, warnings and faults in the machine as well as to production data. All of these data can be stored and archived on a stand-alone industrial PC and displayed in a dashboard that is accessible via any current browser. The system architecture can thus be integrated in a company network without requiring additional hardware. Rossow: “This tool was a particular requirement of our maintenance department. It also gives us the opportunity to optimize the plant performance thanks to the accomplished transparency. This is really very helpful.”

Rapid action unit: a total of four Delta-3 Pickers fill the cartons according to a nested packing scheme in three or four layers.

Rapid action unit: a total of four Delta-3 Pickers fill the cartons according to a nested packing scheme in three or four layers.

Cheese wedges are not aligned upstream of the packer

The entire project was carried out by A+F on a turnkey basis, including the operator training. Besides the Flexline, the order included the mechanical and control-side connection to the cheese cutter, the thermoforming line as well as the remaining manual removal that forms the actual interface. “It had to be implemented in such a way that we could continue using manual removal for the remaining third of our cheese wedges. Operation can therefore take place via manual removal or the machine. Everything is functioning very well”, Katharina Rossow sums up.

The plant components were delivered as planned on 02.02.21. Just one week later the first cheese wedges were passing through the plant. These are conveyed from the remaining manual workstation to the Flexpicker by a product conveyor. Instead of being aligned they are left arranged in a rather “chaotic state”. At the infeed a barcode recognition system checks the cheese wedge from below for the correct product allocation. In addition, the cheese wedges are scanned for any intermediate top film roll changes from the upstream thermoforming line. Cheeses with an incorrect barcode or a detected top film change are discharged.

3-D inspector detects shape, position and orientation

After the inspections the cheese wedges are distributed on two lanes. On both lanes a 3-D inspector records the wedge shape, its position and the orientation of the cheese. This information enables the Delta-3 picker to approach the cheese wedge in the right position, pick it up and place it in the unfolded shoulder tray. The wedge is picked up by a vacuum that is generated using compressed air by means of the Venturi effect, similar to a water jet pump. This allows the suction head a freedom of movement that would not be possible with a vacuum pump.

Identical control for basic machine and robot arm

The actual Delta-3 Picker is a servo-driven robot arm which besides the x, y and z axes has a rotary axis and a tilting axis. In this way it can move to any position in its operating range. Both the basic machine and the robot arm have an identical control system which is beneficial for the customer regarding operation and maintenance.

The wedges passing the first picker, which are within the respective movement radius but cannot be detected in the time window, are then processed by the second of all in all four pickers. The wedges not picked up by the second picker are then picked up by the third picker and those not picked up by the third picker are finally picked up by the fourth picker. If a cheese wedge cannot be picked up due to drawn in secondary air, it is discharged via a chute into a discharge box downstream of the fourth picker.

Satisfied in every respect: “The solution simply corresponds to all the requirements set out by Sachsenmilch“, says Katharina Rossow, Project Engineer for Technical Projects at Sachsenmilch.

Satisfied in every respect: “The solution simply corresponds to all the requirements set out by Sachsenmilch“, says Katharina Rossow, Project Engineer for Technical Projects at Sachsenmilch.

“We at Sachsenmilch are very satisfied with the implemented job“

The carton erector integrated in the plant with a folding station as special version doubles the cardboard at the front access to the product parallel to the packing process. The ready-sealed cartons are placed on an inclined carton conveyor. The control cycles these cartons corresponding to the filling level in the infeed. The carton stream and the cheese wedge stream flow in opposite directions. Each of the four pickers has access to two cartons. If, for example, one of the cartons is filled and moves to the shoulder closer, this design allows the picker to continue feeding the second empty carton. If, on the other hand, a carton that is not completely filled moves on one position further, the cheese wedges are packed into this carton by the next picker. By way of a counting function, the pickers know exactly how many cheese wedges still need to be inserted into the respective carton.

In this way, the four Delta 3 pickers fill the cartons in three or four layers according to a nested packing scheme. The shoulders are then closed on the filled carton before it is moved to the take-off roller conveyor for manual removal. There are two operators on duty per shift to ensure a safe and reliable operation of the automatic cheese wedge packaging. “We have now gained so much potential that we can mechanically pack our maximum cutting capacity”, Rossow comments. Does this positive outlook also mean an equally positive conclusion for the project? Absolutely, Katharina Rossow stresses: “Everything was carried out according to schedule and within budget. Putting it in a nutshell: At Sachsenmilch we are very satisfied with the job done, both on the production and on the maintenance side.“

You want to read more? Find here the full report as a download.

Published in: International DAIRY magazine, December 2021