Compact, flexible, powerful

Emmi AG, Switzerland, invests in a state-of-the-art packing and palletising solution for thermoforming trays

Raclette does, of course, have a definite peak season. But there is also a stable demand beyond the cold time of the year. So stable, in fact, that the Swiss Emmi Group invested in a state-of-the-art raclette cheese slicing plant last year. Key components are a combi-packer for wrap-around cases and plastic crates and a multifunctional robot palletiser.

Switzerland, dairy, Emmi – that’s rather like taking owls to Athens. Emmi is Switzerland’s largest milk processor with a strong international presence, well ahead of its competitors. In 2023 the Emmi Group generated sales of CHF 4.232 billion, slightly higher by 0.3 percent than in the previous record year of 2022. Organic growth amounted to 3.5%. Strategically important markets such as the USA, Brazil and Chile as well as Switzerland have been particularly successful.

The case packer inserts the thermoformed trays into wrap-around cartons (left) and two returnable plastic containers (right).

The case packer inserts the thermoformed trays into wrap-around cartons (left) and two returnable plastic containers (right).

Also very popular for cheese burgers

In this connection, a significant role is played by the cheese segment, including the famous raclette cheese. But isn't raclette synonymous with cold, snow and Christmas? Not at all, explains Martin Küttel, the responsible value stream manager at Emmi: "Demand is, of course, about three times higher in the cold months. But there is also a stable demand for raclette during other times of the year. The cheese is very popular in cheese burgers, for instance." Emmi therefore decided to discontinue two existing raclette slicing lines and build a completely new line at the Emmen site. With clearly defined investment goals. "First of all, we wanted a significantly higher output. Our second objective was to implement automation. Previously, this was only the case with carton packaging. We processed the returnable packs, typical for Switzerland, manually, this also being the case for the entire palletizing process," Küttel explains.

Wrap-around as an attractive alternative

There were three decisive reasons in favour of the solution implemented in 2023, Küttel points out: “What we actually wanted was a two-part carton again. But then we had the option of the wrap-around, which saves us money.“ The second main reason, according to Küttel, was that Emmi can now process both the carton as well as the reusable pack on just one machine. “All other suppliers would have required two machines for this, which in turn would have taken up more space, among other things.“ And thirdly: „Our current palletiser performs all the tasks with just one single gripper head. Other suppliers would have needed twice as many.“ Küttel adds.

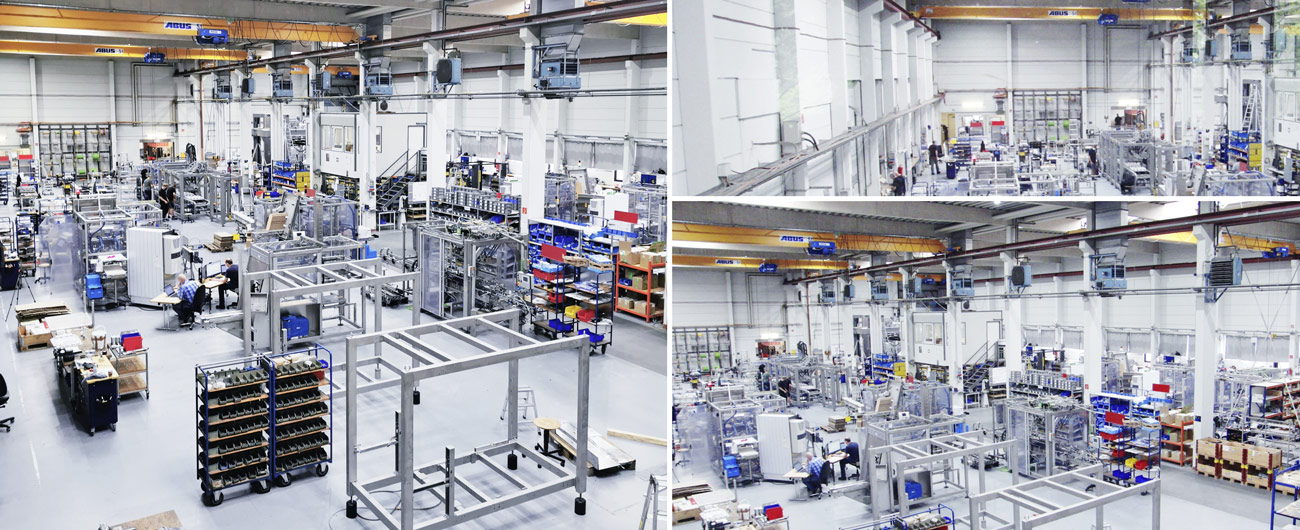

New design made up of proven modules

The order was for a ModuLine case packer for thermoforming trays in wrap-around cases and two returnable plastic packs. This packer is a new design based on existing and proven machine modules – it is currently a unique model. The order also included a robot palletiser and depalletiser for returnable packs, wrap-around cases as well as layer pads, the necessary conveyors for returnable packs, wrap-arounds and pallets as well as a turntable stretch wrapper and a pallet labeller. The entire project was completed on a turnkey basis.

All palletising and depalletising tasks, including the application of intermediate layers, are performed by just one gripper head.

All palletising and depalletising tasks, including the application of intermediate layers, are performed by just one gripper head.

The pack and palletising unit was approved in December 2023. It has been performing well since then in everyday use for the following processes: The aligned thermoforming trays are taken from the customer’s conveyor in one lane with the short side leading and the decor on top, and are then conveyed into a cavity where they are stacked. Six cavities are attached by means of quick-release fasteners to a cell chain arranged in a square with two pulls. Once the cavities have been filled, they are cycled to the 2-axis portal where they are then lifted. The 2-axis portal lifts the stack using a gripper and, depending on the programme selection, places the stack in the tray that has been pre-folded from the flat blank, or in one of the two returnable packs. It is important in this process that the length and width packing parameters do not change.

Grammage defines the height of the packaging

The packaging height, on the other hand, is variable depending on the desired grammage. Küttel explains: "The tray as packaging type is a very volatile market. New grammage was already requested during the course of the project.“ This entailed substantial programming work in order to ensure the required flexibility for the packer. With success: “We can now make the necessary adjustments here on the machine“, Küttel adds.

The trays are then glued around the product using hot melt and then discharged to the side. The filled returnable packs are also conveyed to the palletising area via conveyors. Maximum energy efficiency was ensured in all areas by a closed loop servo drive system in the axis arrangement, for example, or by lowering the temperature of the gluing unit when not in use.

The wrap-around solution replaces a two-part carton: ‘This saves us costs.’

The wrap-around solution replaces a two-part carton: ‘This saves us costs.’

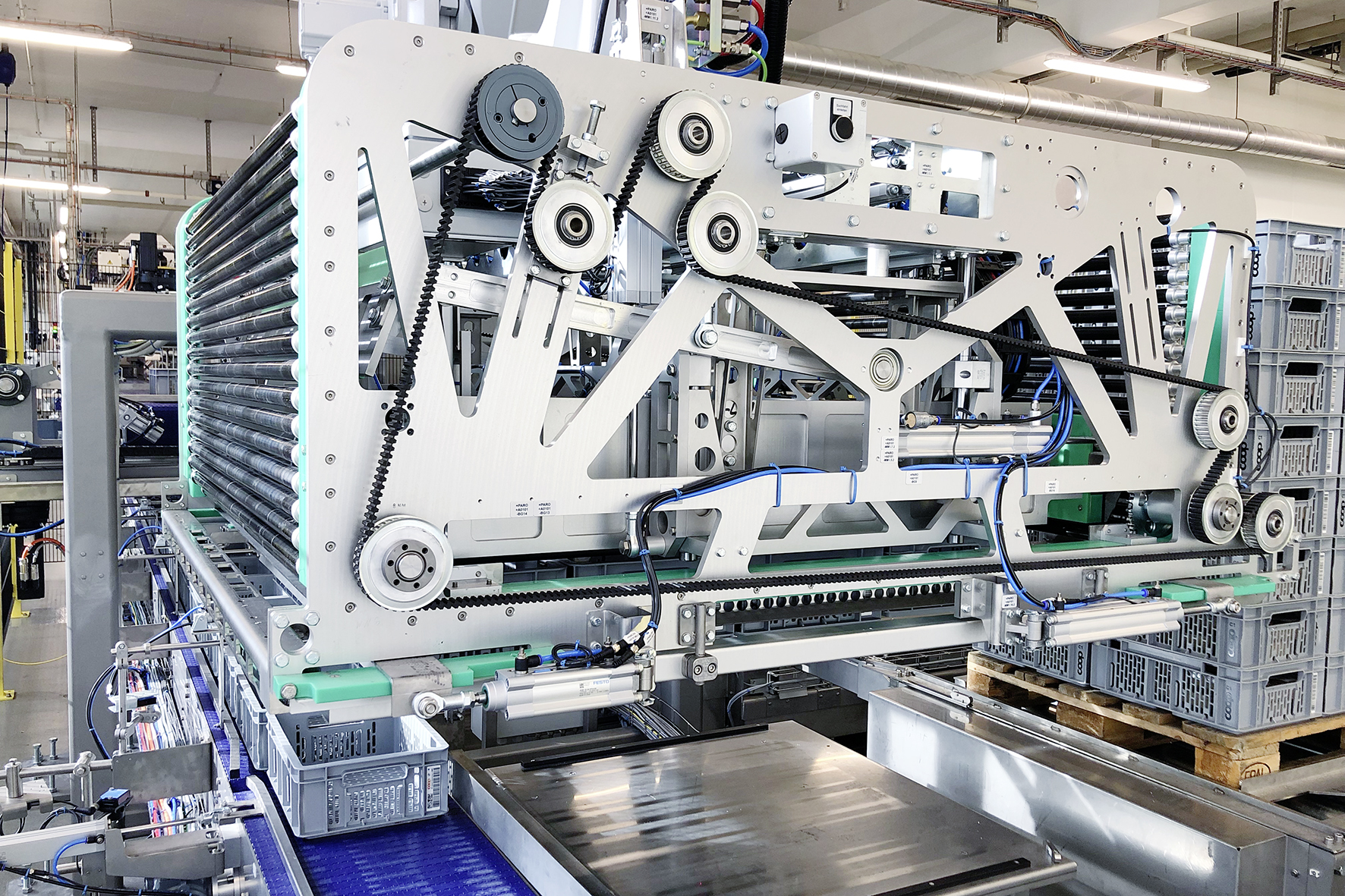

Accomplished with a single palletising head

In the robot palletising cell, both the empty returnable packs are depalletised from the carrier pallets and fed to the packer and also the full returnable packs and wrap-around cases coming from the packer are palletised and the layer pads inserted. This is all accomplished with a single palletising head. “We have three different types of secondary packaging, two different pallet types as well as a layer pad for the cases. And with a limited amount of space. The robot saves space and, with its multifunctional gripper head, it is much more flexible than other palletising cells“, Küttel explains.

The palletising cell was integrated in the overlying ERP system. This sends the required data for the respective palletising order to the robot, which automatically adjusts to it. The palletising is thus controlled by the ERP system. The same applies to the application of the required pallet label. Manual acquisition of data at the palletiser is not required. Another software tool is the Condition Monitoring. This programme creates statistics, documents any system errors and allows a system analysis via the internet.

The robot palletiser also feeds the returnable packs to the packer.

The robot palletiser also feeds the returnable packs to the packer.

„We are now really well positioned“

“We remain calm and relaxed as we look ahead to the next peak season. We are really well positioned with our new raclette line“, Küttel sums up. An important tool in this successful project handling was the construction site management system LOP 4.0. LOP 4.0 is a cloud-based system to which all parties involved in the project have access. This digital platform maps the project status with the highest possible transparency during the construction site phase, from the delivery right up to commissioning. LOP 4.0 is furthermore an open communication and documentation platform. Each project partner can, for example, upload photos or videos, propose next steps for discussion or prioritise individual items. This makes sure that the presentation of the status of all project modules is always up-to-date and clearly understandable. Any interactions with the next steps can thus be seen immediately. This reduces conflict and coordination losses and leads to a high level of planning ability – and customer satisfaction. And as they say: only a satisfied customer is going to place the next order. This was obviously the case for Emmi – the order for another packer and case erector has already been placed with the EOL Group.