Five modules for maximum transparency

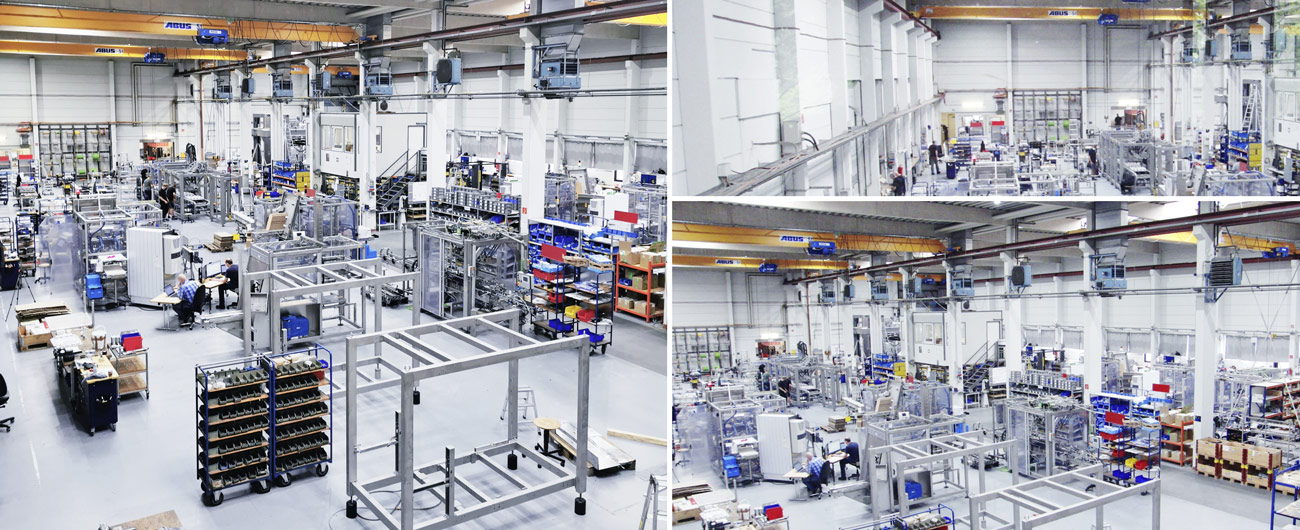

At A+F Automation + Fördertechnik GmbH Digital Packaging has long become the norm

As with steam, electricity and automation, digitalisation is set to revolutionise the way we work. This applies most particularly to complex processes such as the packaging of beverages and food. A+F Automation + Fördertechnik GmbH was quick to address this challenge and has already launched two digital tools with its modules “Digital Twin” and “Condition Monitoring”. Both of these modules represent the first building blocks leading up to a fully digitalised packaging line. The mission of this digital packaging strategy is to optimise the overall performance of a plant or machine throughout its life cycle. Digital packaging therefore starts with the design of a machine or plant; it incorporates the continuous status diagnosis and ultimately ends with its proactive performance.

In its final stage, the digital packaging programme will include the following five modules:

- • Digital Twin

- • Condition Monitoring

- • Performance Diagnostics

- • Predictive Maintenance

- • Digital Spare Parts

The five modules complement each other and can therefore be implemented successively. The upgrading of existing plants or machines is also possible in many cases.

The Digital Twin module

The digital twin module has been applied successfully for several years now. With this tool a computer simulation is used ahead of an investment in order to clarify how the task set by the customer can be implemented in both a technically and economically viable manner. If, for example, completely different brands are to be inserted inline in a tray, all relevant sorting systems can be assessed objectively prior to a real machine test. However, this digital twin offers a lot more than just computer simulation. The tool is designed to drive exactly the same PLC that will be used by the customer, and this in turn drives the simulation. The findings acquired during these tests - practically under operating conditions - help optimise the machine design as well as the later commissioning at the customer’s site.

The Condition Monitoring module

The condition monitoring tool was launched in 2018. Like all of the digital packaging building blocks it is an A+F in-house development. It is used directly at the customer’s site and forms the basis as well as the interface for all of the digital packaging modules. The condition monitoring tool automatically records all data relating to the production, the machine and to the surrounding area. This applies, among other things, to status messages, warnings and machine malfunctions as well as production data. All these data are stored on a standalone industrial PC where they are archived and displayed in graphic or tabular form on a dashboard. With these data it is possible to carry out detailed monitoring of the plant. The service technician and the machine operator are provided with in-depth diagnostics options. Comprehensive production process data are also made available for the production planning. Practice has shown that consistent use of the condition monitoring tool increases the line availability by two to four percent per year on average. Another advantage is that the dashboard can be accessed with any current browser. The architecture can thus be integrated in a company network without necessitating additional hardware or software. The condition monitoring module can also be optionally accessed via the internet.

The Performance Diagnostics module

The third module “Performance Diagnostics” is currently in prototype status. The concept here is to equip the machine with a video system. This system monitors the machine around the clock and saves recordings from ten seconds before up to three seconds after the error as a video in the condition monitoring database. Here it is coupled with the error message. The result is a video on each and every documented error, showing exactly what has happened.

The modules Predictive Maintenance and Digital Spare Parts

Development of the predictive maintenance tool is already well advanced. This module lets the operator zoom into the machine via a dropdown menu, right down to the lowest level: the actuators. General information such as the original data sheet as well as the current status is available for this purpose. For instance, information is provided on the number of strokes performed by a valve. This value is automatically compared with pre-set reference values. When the first value is reached the status display jumps from green to yellow, indicating “Caution”, and when the second value is reached it jumps to red for “Action”. Another example is the power consumption of a servomotor. If this increases significantly it is an indication that damage is likely to occur. The customer therefore no longer conducts a service based on a “feeling” or according to a specified interval, rather on the basis of concrete data. It is planned in the next step for the predictive maintenance tool to independently send e-mails with a status report, also indicating the need for respective action to be taken. The planned Digital Spare Parts module is also located in the service and maintenance sector. The focus here is on the development of electronic parts lists directly on the machine.

Summary

All five digital packaging modules have the same common goal. They are aimed to make the condition of a machine or plant transparent from deep down inside. The data required are already available. The innovative A+F digitalisation is now converting them into hard facts and clear actions – in the interest of both investors and machine builders.

You want to know more? Find HIER the full report!

Published in: LVT Lebensmittelindustrie / August 2021