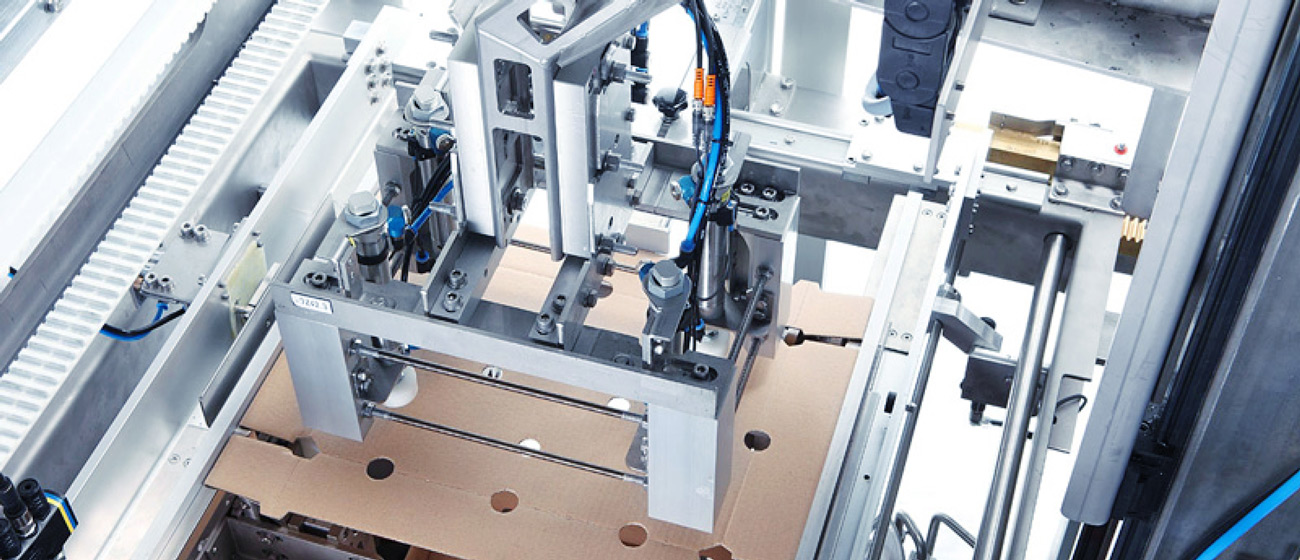

Case and tray erectors for every output range

Erectors "Made in Germany”

Whether cost-effective entry-level configuration or compact all-rounder - the A+F case, tray and crate erectors meet the highest demands on quality, reliability and efficiency.

Through the consistent use of servo technology, the tray and crate erectors achieve an output of up to 60 trays/minute - with absolutely constant forming. Over 25 years of experience and continuous use by customers stand for the quality and durability of our tray and crate erectors.

A+F erectors

A+F erectors: overview of technologies

High performance level

With performance levels of up to 60 trays or 150 cartons per minute with simultaneous shape accuracy, the erectors from A+F GmbH play in the top league.

Compact design

With ergonomic design for optimal operability, the erectors impress with their reduced space requirement and compact design, and thus have only a minimal space requirement.

Flexible usage options

High flexibility in terms of formats, carton shapes and material specifications and wide format range with short makeready times of less than 10 minutes - with immediate resumption of production after format change.

A+F Machines

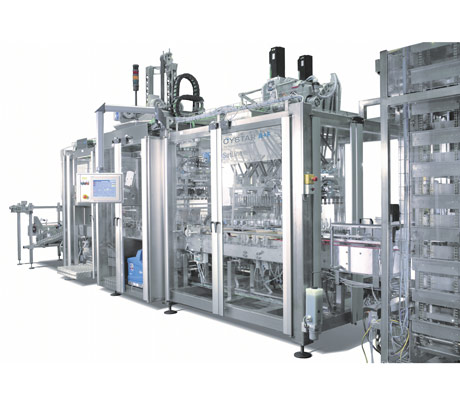

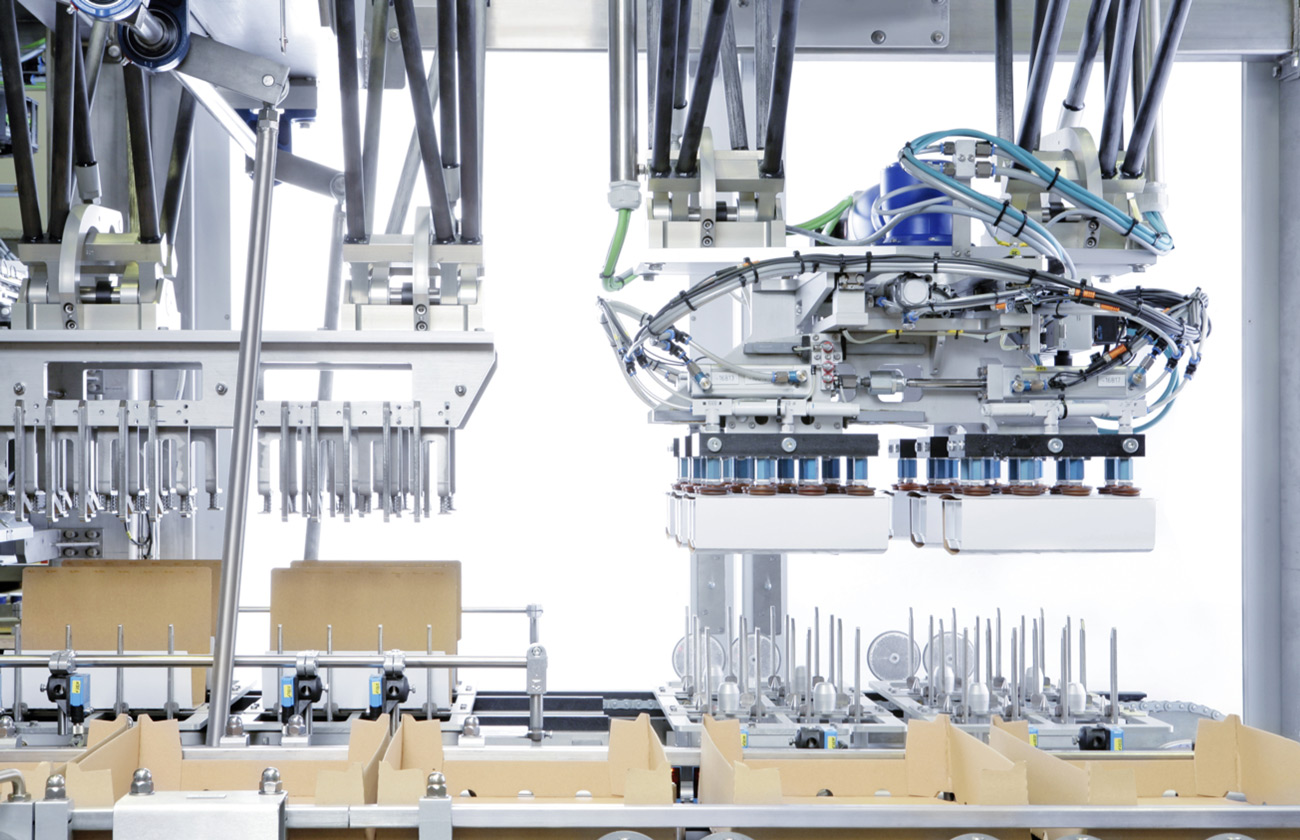

Sleeving machines for every output range

Sleeving machines „Made in Germany”

The A+F sleeving machines are multifunctional packaging systems with integrated sleeve application for the realisation of a wide range of packaging tasks. The packaging systems process single cups, cup sets and bottles of various shapes and sizes.

With the packaging system, the customer decides how the products are presented to the end consumer. Whether as a set of cups, individual cups or bottles, packaged directly in a tray or crate, or further packaged with a full sleeve suitable for presentation - everything is possible.

A+F sleeving machines

A+F sleeving machines: overviews of technologies

Modular plant concept

The modular system concept allows the configuration to be adapted to customer-specific applications.

Flexible usage options

The SetLine allows flexible processing of individual products or sets in defined pack formats - with short set-up/changeover times.

A+F Machines

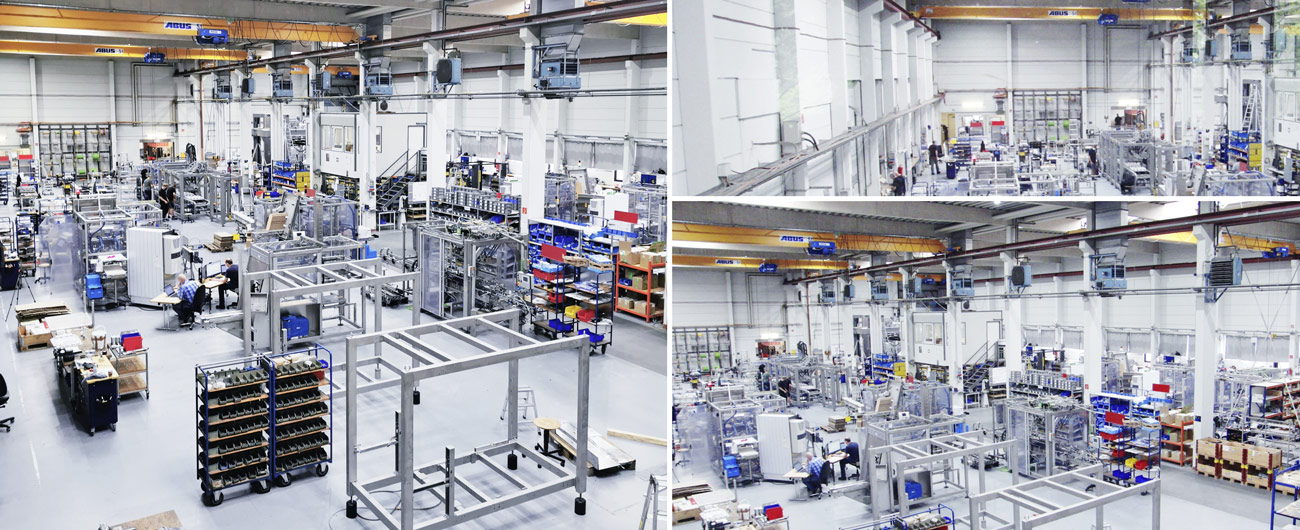

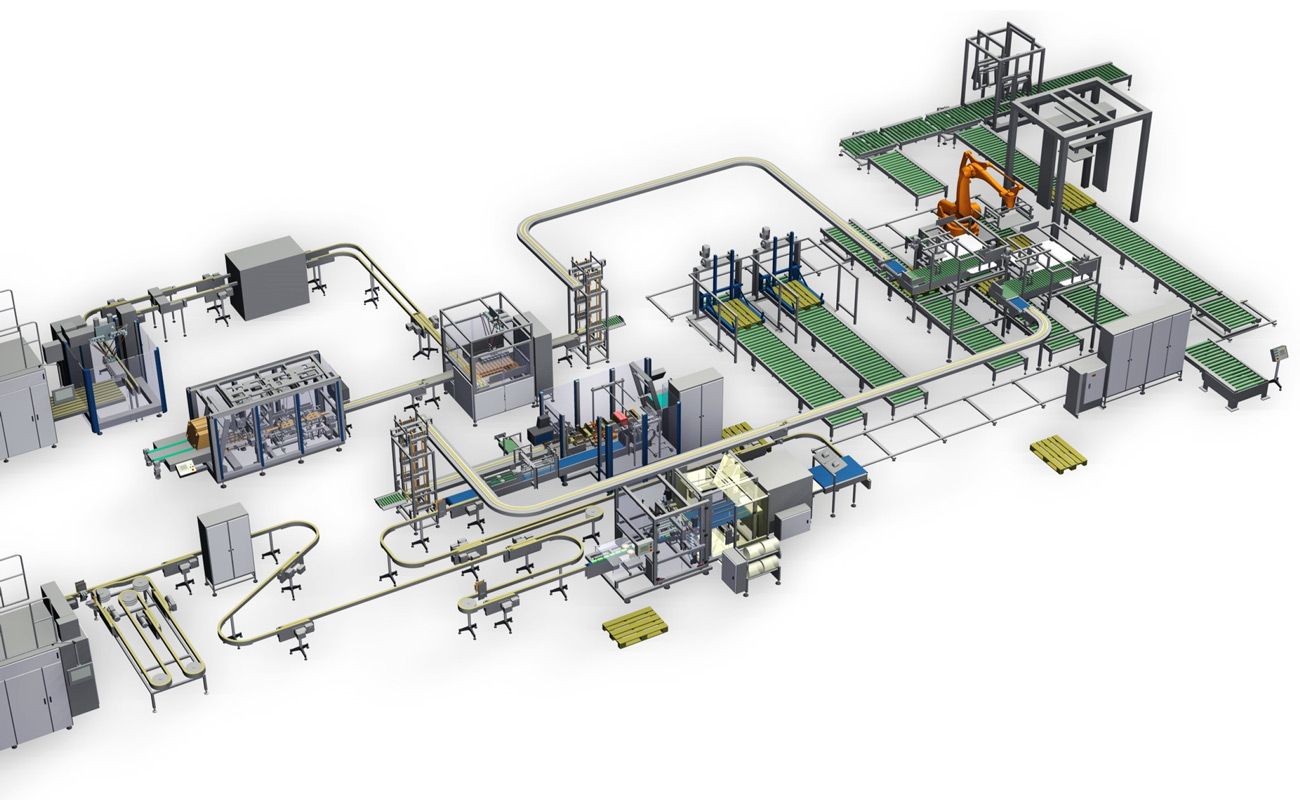

A+F Overall systems

From project planning to acceptance

The delivery of complete line concepts is an outstanding feature of A+F. Many years of experience in customer-specific line and plant planning as well as their implementation with installation and commissioning have shaped the company. For a wide range of industries, it is possible to plan and project the lines, the packaging lines or large parts of a plant. The product-specific requirements for the lines are taken into account.

The project planning of a line starts mainly with the filling machine, the subsequent primary product transport with buffer systems, the packaging machines including coding systems, the carton conveyors , the optional carton shrinking systems, the palletising systems, the empty and full pallet transport, the pallet wrapper as well as the pallet identification by labels and the transfer to the high-bay warehouse or similar. Today, a very important connecting element of the individual system components are the higher-level control systems or the connection to the customer's ERP system. Here, the primary data such as article number, BBD, batch number, quantities per carton or pallet are generated and forwarded to the packaging machines. Finally, all the necessary information must be available on the pallet label.

As a system integrator, A+F is able to connect the various interfaces.The integration of systems that cannot be manufactured by A+F is also part of the range of services. A+F offers complete lines, from consulting to project planning, from installation to commissioning, from integration to acceptance.

A short reference list of A+F customers, which also includes, for example, the following global players: Zott, Danone, Friesland Campina, Yoplait, Nestle, Unilever, Kerry Foods, Arla Foods, Conagra Foods, Kraft Foods, Kellogg`s, General Mills, Refresco, Tnuva, Ehrmann, Almarai, Müller Group, Tetra Pak, Develey, Green Mountain Coffee, Bauer, Morinaga, Leche Pascual

Technical Performance Characteristics

- The system planning includes consulting work and engineering of the production lines as well as providing the final offer.

- The support includes extensive layout drawings as well as calculation of the machine speed and output, sleeving concepts, carton layouts, palletizing patterns, layer inserts and product sheets.

- The extensive A+F product range includes traypackers, tray and case erectors, packing and sleeving systems, robot palletizers, layer plate palletizers, conveying systems for products, cases and pallets.

- Additional purchases of system components are carefully selected and integrated. All are tested at the suppliers premises. Prior to delivery a final acceptance test is performed.

- Customers can choose from a large variety of PLC control systems.

- Experienced project managers are assigned to be the key contact for the customer during the lifetime of the project. He will manage all dates, sample materials and final test of the equipment amongst other things.

- Key system components will be commissioned at A+F and an acceptance test is done with the customer.

- Set up and commissioning at the customer’s facilities is done or supervised by experienced A+F service technicians. At the end a final acceptance test is performed to complete the project.

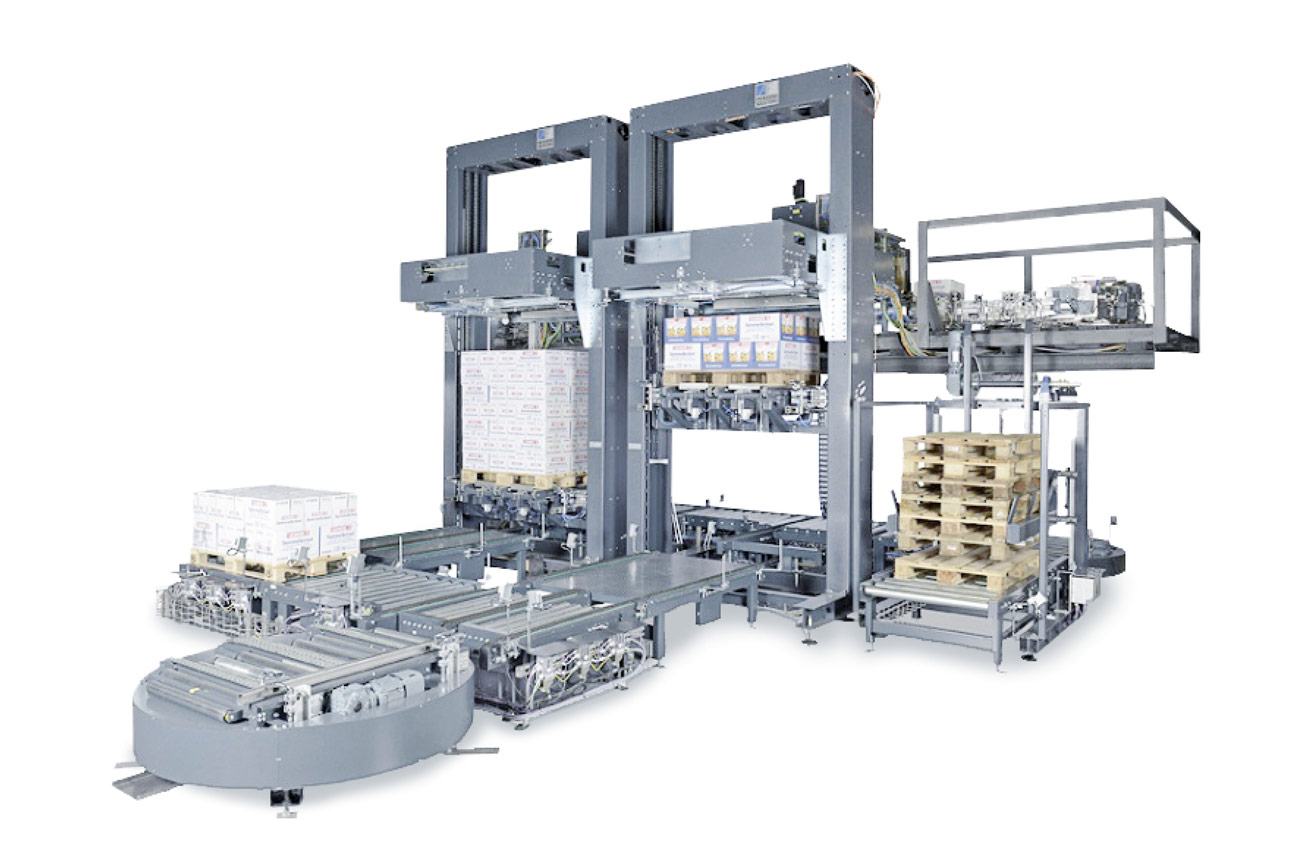

Layer sheet and robot palletisers for every performance range

Palletising technology "Made in Germany"

A+F offers palletising robot systems as well as standard palletising systems as layer sheet palletisers and integration into the production environment.

All A+F palletising systems are modularly designed and built. They are based on years of experience and technology that has proven itself in a wide range of industries. Our complete system solutions including the integration into the pack infeed from the packing machine, the empty pallet magazine and supply as well as the full pallet transport to the loading or to the high-bay warehouse distinguish the flexibility and quality of these machines.

A+F palletisers

A+F palletisers: overview of technologies

Ergonomic design

Thanks to a modular machine concept with extensive technical options, the ergonomic design ensures optimum operation.

Flexible usage options

The palletisers offer a choice between conventional palletisers for high loads and output levels up to 400 layers/hour or robotic palletising for maximum flexibility.

Low maintenance costs

Due to high-quality, low-maintenance design, because before delivery, all systems are run in with original sample material and subjected to a documented final inspection.

A+F Machines

A+F Solutions for the paper industry

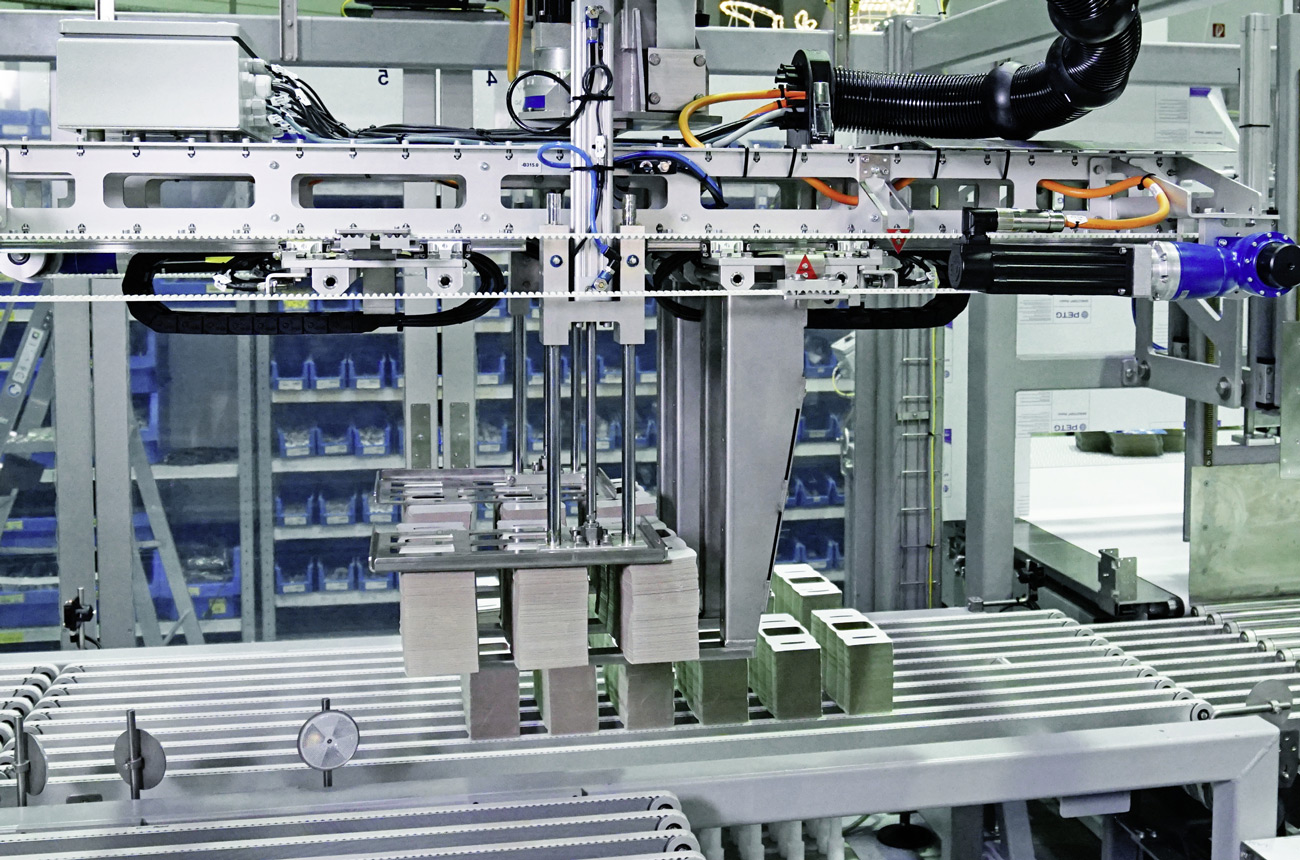

Paper stack transport systems and the carton stack packer PaperLine

Rely on globally proven solutions for paper stack transport based on conventional or robot-assisted control.

With the A+F PaperLine case packer, you can process up to 600 cases per hour - whether open cartons, wrap-around cartons, shoulder cartons or cartons with lids. Find out more here.

Paper Stack Transport System

Manage different stack heights of different products with just one system – also featuring a high load capacity and a fully automatic format changeover. You are looking for a paper stack transport system with low service and maintenance costs? ? A+F has the perfect mix for you, featuring a well-proven interface design, small roller radii and safe and reliable product handling. An experienced project manager from A+F will supervise your project from scheduling to selection of sample material up to acceptance of the plant. A contact person for all key issues as well as highest quality and efficiency based on CE or UL certified plants and components.

We offer you proven quality “Made in Kirchlengern” and develop together with you an overall concept for your plant which meets your every wish in terms of flexibility, changeover times and blanks. You can, of course, equip complete plants with a free line preselection – our experienced A+F Service Team will be happy to advise you without any obligation.

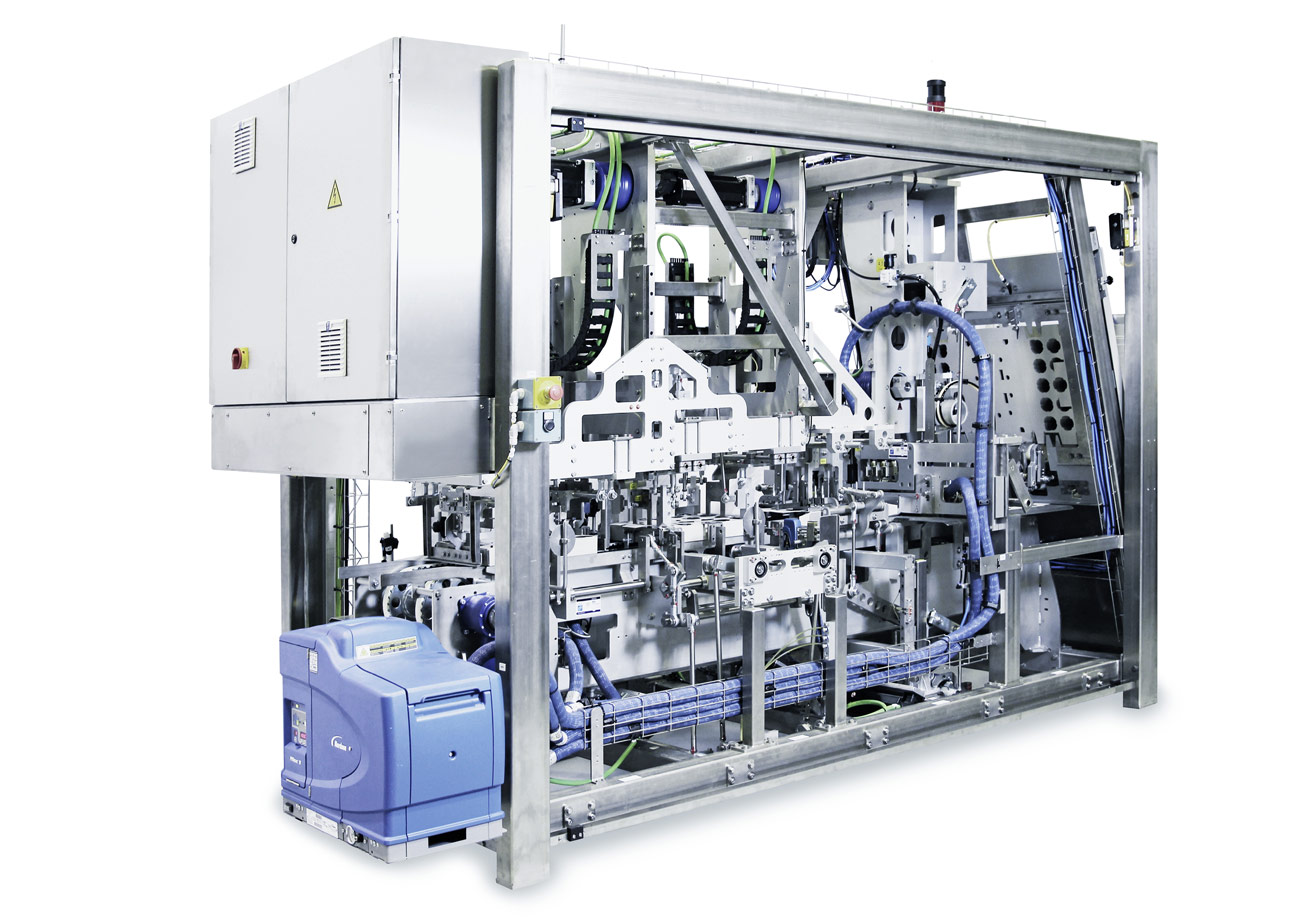

Carton Stack Packer PaperLine

The carton stack packer A+F PaperLine provides a light barrier protected pallet transport for highest safety standards. You are looking for a reliable, fast and low maintenance design? The A+F PaperLine offers an efficient product infeed and product collation directly downstream of the stacking unit of the stamp. Complete machine enclosure guard, a secure access to the depalletising area as well as the complete pre-installation of electrical and pneumatic systems are just three aspects of the benefits you enjoy with A+F carton packaging plants.

Choose from various industrial robots from ABB or KUKA, benefit from an easy-to-operate ELAU or Schneider control system for blank control and optionally expand your system with a fault message analysis with advanced fault message display. We would be happy to advise you on the best possible plant design for your specific needs.