Case and tray erectors

Tray Erector SHL-THL-V

Optimise your performance and rely on the SHL-THL-V Tray and Case Erector. You want to erect up to 60 trays per minute with an absolutely constant form? You can do this with our products because they are designed for continuous operation and always use state-of-the-art servo technology. Benefit from over 25 years of experience, use a wide format range with short setup times (less than ten minutes) and produce trays and cases in just one machine. Durable technology, simple operation – that’s what A+F tray and case erectors stand for.

Tray Erector SHL-THL-V in detail

Benefits

- High performance level of up to 60 trays/slides per minute with simultaneous format accuracy

- Compact design with reduced space requirement

- Wide format range with short set-up times below 10 minutes - with immediate resumption of production after format change

- Production of trays and trays in one machine

- Low production costs due to high-quality, low-maintenance design

- Ergonomic design for optimal operability

- High-quality design and durable technology

Technical data

- Capacity:

SHL: 3,600/h

SHL-V: 2,700/h

THL-V: 3,600/h - Format:

SHL: 6-24 different formats

SHL-V: 6-24 different formats

THL-V: 6-24 different formats

THL-V: 6-24 different formats - min. W x H x L:

SHL: min. 150 x 180 x 40 mm

SHL-V: min. 150 x 180 x 40 mm

THL-V: min. 100 x 100 x 40 mm - max. W x H x L:

SHL: max. 325 x 410 x 145 mm

SHL-V: max. 320 x 400 x 150 mm

THL-V: max. 310 x 410 x 250 mm - Control:

SHL:Schneider Electric / Allen Bradley

SHL-V: Schneider Electric / Allen Bradley

THL-V: Schneider Electric / Allen Bradley

Applications

- Erecting trays and perforated crates from flat blanks

- Binding: Open trays as well as perforated trays - standard or customer-specific

Options

- Integration into the overall line, consisting of filler and packer or connection to packing machine

- Additional or replacement tools for quick format changeover

- Transport lines for conveying trays / perforated trays into the production environment

- Customised and application-specific configurations and technical solutions

A+F erectors

Case and tray erectors

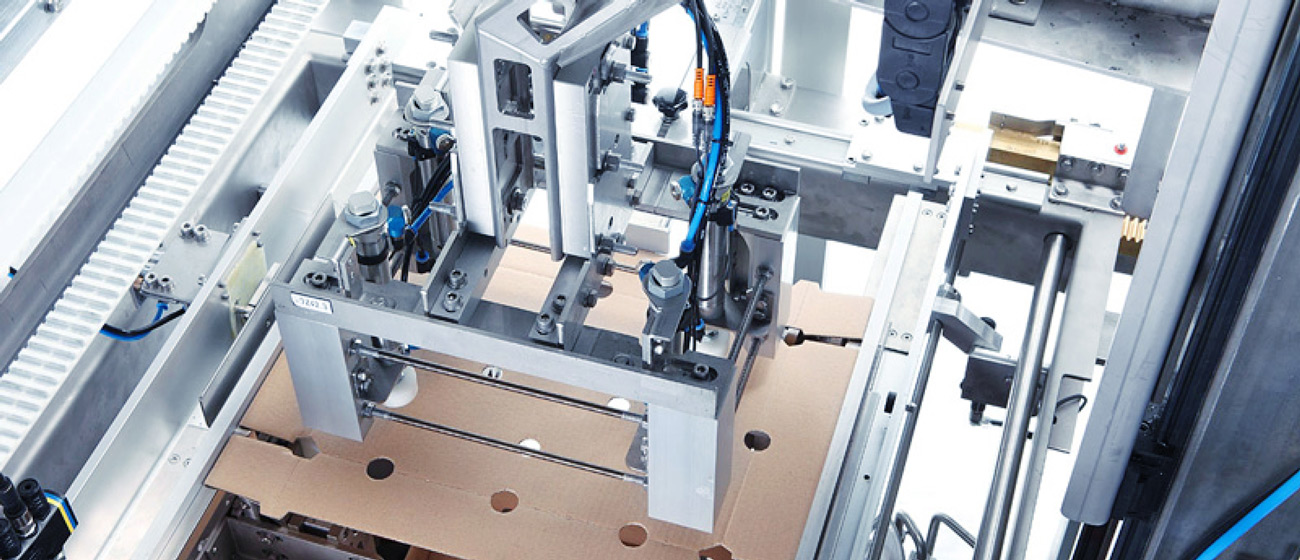

Tray Erector MultiFormer

Handle the erecting of cases in just one step using the proven stamping principle. You want to feed packaging lines with a central supply of cases? This is possible with the A+F MultiFormer as it can be configured as required and integrated into existing lines. Whether as an integrated tray erector in your production lines or generally for the central supply of your packaging lines. Benefit from high performance (40 to 150 cartons per minute) and high format accuracy with short changeover times – always adaptable to your needs and the blanks to be formed. Your investment risk is thus reduced and you can react flexibly to changing market conditions.

Tray Erector MultiFormer in detail

Benefits

- Single to 4-lane configurations ranging from 40 to 150 cartons/minute

- Minimal space requirement due to compact design as well as fast, uncomplicated installation

- Use as erector for high-quality secondary and transport packaging

- High flexibility with regard to formats, box shapes and material specifications

- High format accuracy and short changeover times through the use of application-specific format parts

Technical data

- Performance: 2.400 – 9.000 Trays/h

- Control: Schneider Electric, Allen Bradley

- B x H x L: min. 150 x 150 x 30 mm

max. 410 x 410 x 150 mm

Applications

- Erecting rectangular boxes and special shapes from flat blanks (solid or corrugated board)

- Container: boxes and open trays with straight side walls

Options

- Integration into the overall line, consisting of filler and packer or connection to packing machine

- Additional or replacement tools for quick format changeover

- Transport lines for conveying erected cartons / trays into the production environment

- Customised and application-specific configurations and technical solutions

A+F erectors

Case and tray erectors

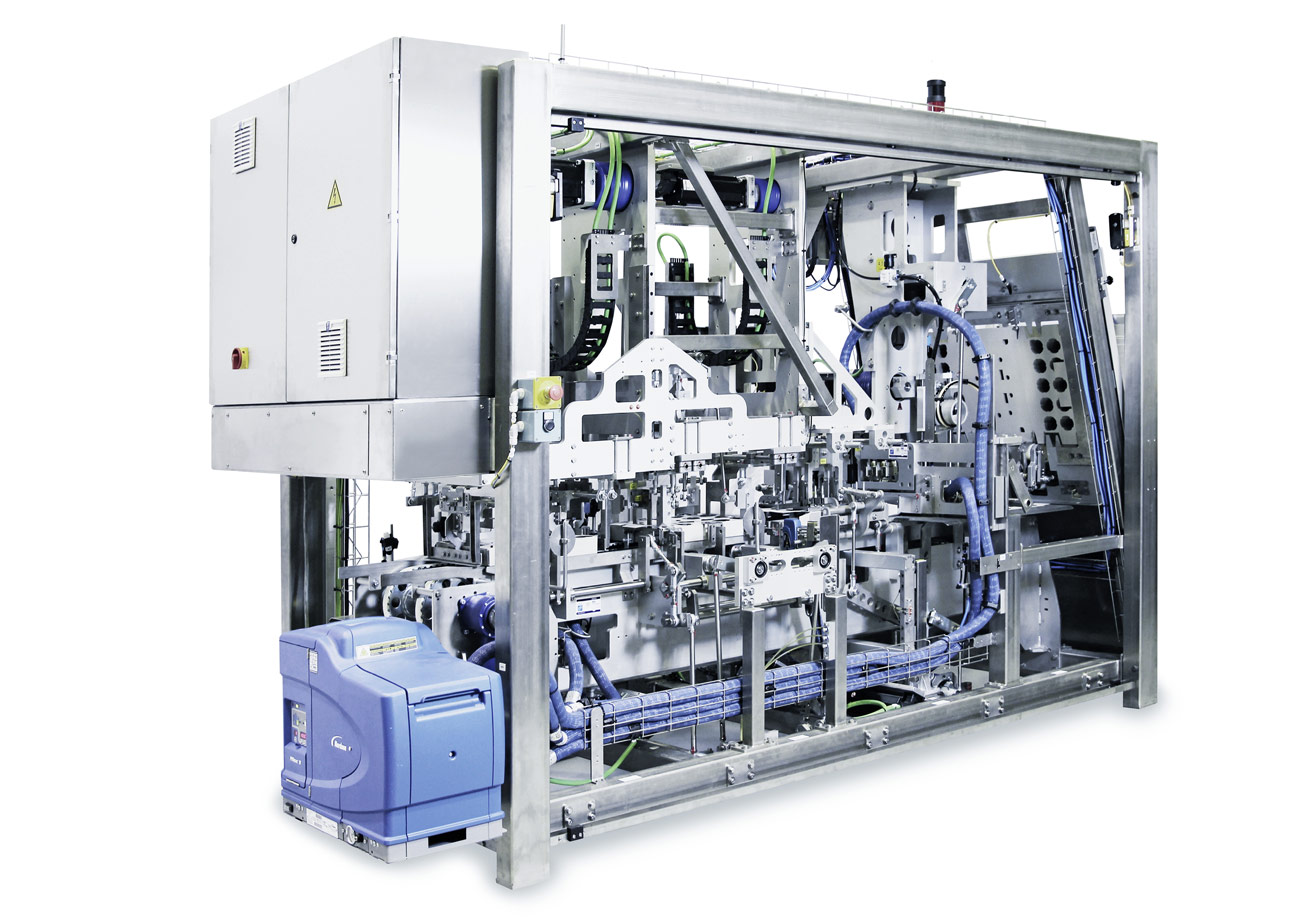

Tray Erector 216s

Ensure the precise forming of erected trays and cases every time. You want a high output with consistent forming? The A+F Tray Erector 216s offers you the perfect mix of high performance level, absolute format accuracy and reduced footprint. Produce crates and trays in just one machine, with ergonomic operation and a long service life thanks to a maintenance-free design. With up to 60 trays/cases per minute, short tooling times of less than ten minutes and an immediate resumption of production after format changeover.

Tray Erector 216s in detail

Benefits

- High performance level of up to 60 trays/slides per minute with simultaneous format accuracy

- Compact design with reduced space requirement

- Wide format range with short set-up times below 10 minutes - with immediate resumption of production after format change

- Production of trays and trays in one machine

- Low production costs due to high-quality, low-maintenance design

- Ergonomic design for optimal operability

- High-quality design and durable technology

Technical data

- Performance: 2.700/h

- Format: bis 6-24 different formats

- Control: Siemens S7

- B x H x L: min. 100 x 100 x 40 mm

max. 310 x 410 x 250 mm

Applications

- Erecting trays and perforated crates from flat blanks

- Binding: Open trays and perforated trays - standard or customised

Options

- Integration into the overall line, consisting of filler and packer or connection to packing machine

- Additional or replacement tools for quick format changeover

- Transport lines for conveying trays / perforated trays into the production environment

- Customised and application-specific configurations and technical solutions