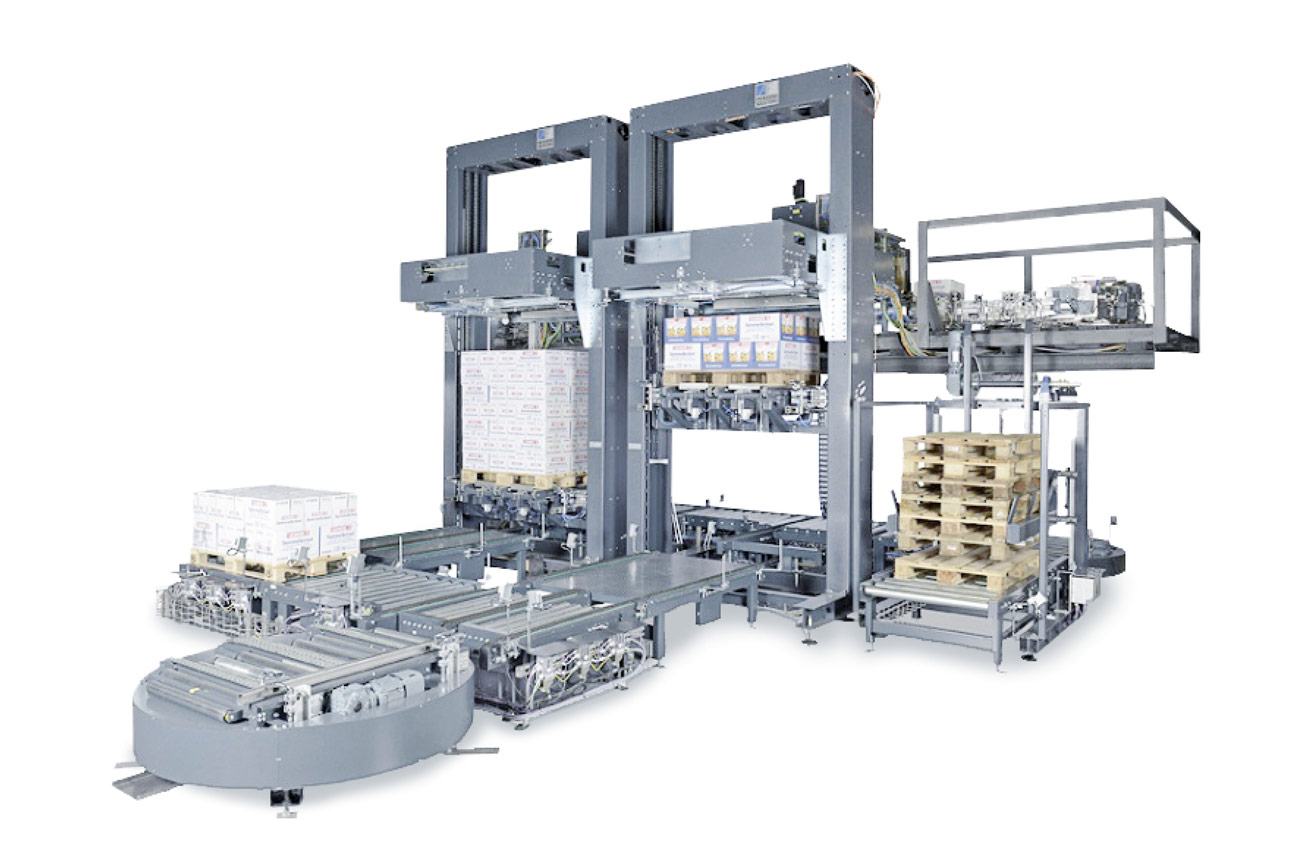

Palletiser

Layer-Plate Palletiser 350Q / 355Q

Benefit from a palletising system that is tailored to you specific needs. You want to reduce maintenance costs and reach a high output? Then choose our high-performance A+F layer-plate palletisers, designed as a palletising robot system or standard palletising system. They can be integrated in your production environment at any time and are designed for up to 400 layers per hour, even with heavy loads. Thanks to their modular design they are suitable for any sector, designed for parallel handling of up to four production lines and serve as a system solution with any level of integration. A+F layer-plate palletisers offer you maximum flexibility and are designed for all product, layer pad and pallet handling variations.

Layer-Plate Palletiser 350Q / 355Q in detail

Benefits

- Modular machine concept with extensive technical options

- Proven technology and many years of experience in a wide variety of industries

- Choice between conventional palletisers for high loads and output levels up to 400 layers/hour or robotic palletising for maximum flexibility

- Comprehensive solution approach including infeed, empty pallet supply and full pallet transport

- Low maintenance costs due to high-quality, low-maintenance design

- Ergonomic design for optimal operability

- High-quality design and long-lasting technology

Technical data

- Number of axes:

Robot palletising: up to 6

Standard palletising: / - Maximum load:

Robot palletising: 450 kg

Standard palletising: 180 kg/pallet layer - Power:

Robot palletising: up to 5 depositing cycles / minute

Standard palletising: up to 400 layers / hour - Control:

Robot palletising: KUKA, ABB

Standard palletising: Siemens, Allen Bradley - Lines:

Robot palletising: up to 4

Standard palletising: up to 2 - Additional handling:

Robot palletising: layer pads, empty pallets

Standard palletising: layer pads

Applications

- Appliactions: Palletising

- Containers: All cardboard packaging, trays, perforated trays, crates and film containers

Options

- Overall solution / logistical concept internal

- Interface to systems for intelligent warehousing

Select your language