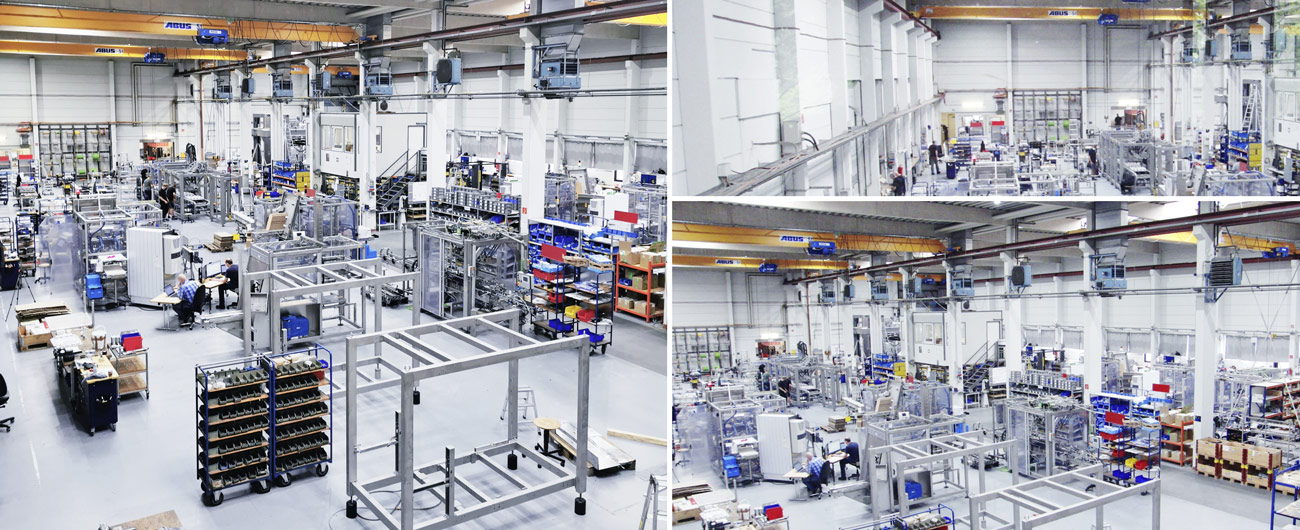

Sleeving machines

Sleeving machine SetLine

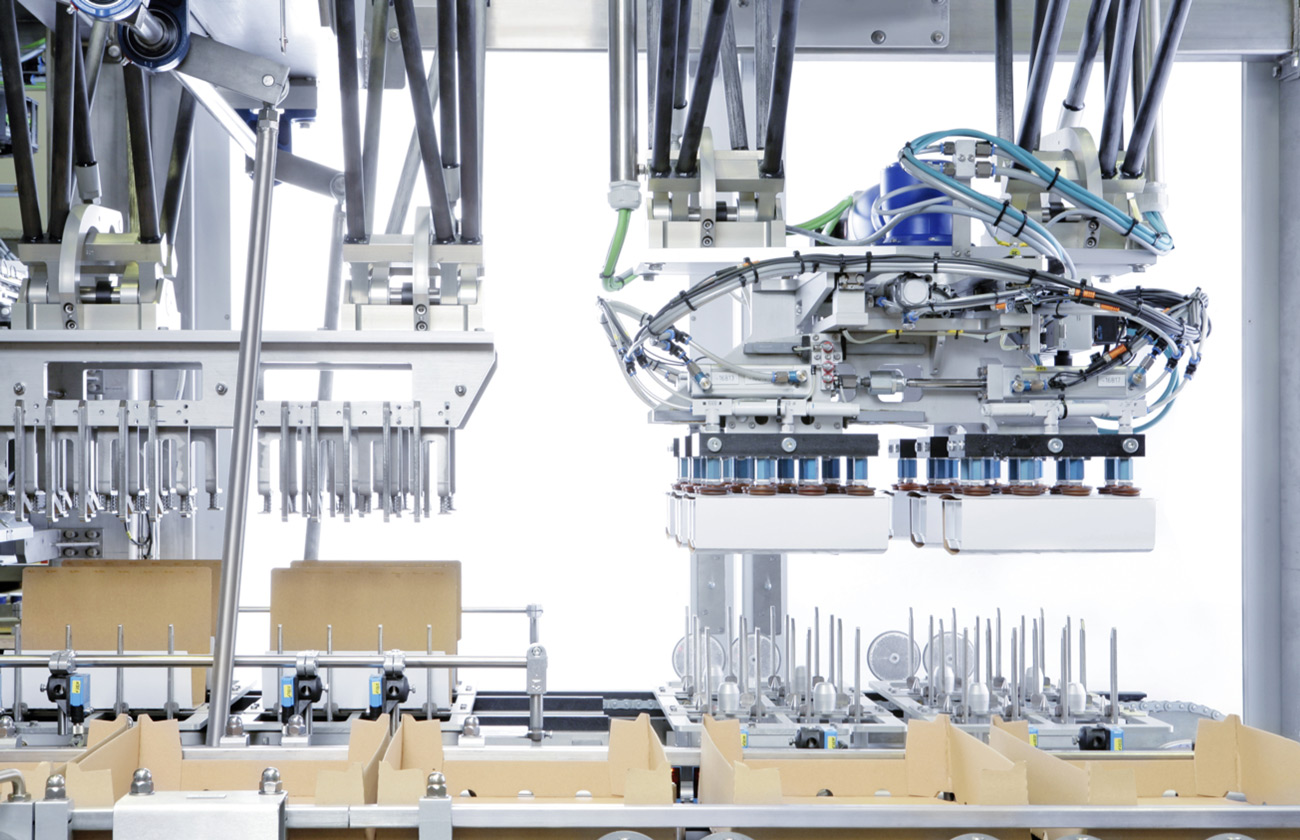

Easy processing of single cups, cup sets or bottles of any size and shape with the A+F SetLine. You would like to connect the packaging plant to your filling line? Create an integrated complete line that offers you maximum packaging flexibility and vast cost savings. Whether packed in a tray, a case or in a full sleeve for presentation– with the A+F SetLine you can create the exact packaging your product needs.

By the way: Thanks to the modular system concept you can adapt the cup sleeving system to your specific applications as required, process individual products or sets in defined pack formats – and optimise your processes cost-effectively thanks to short setup and changeover times.

Sleeving machine SetLine in detail

Benefits

- The modular plant concept allows the configuration to be adapted to customer-specific applications

- Line concepts with significant advantages in overall efficiency

- The integration of several packaging steps in one line allows compact configurations with reduced space requirements

- Filling and sealing of the presentation sleeve is done from above. This is associated with cost advantages due to smaller sleeve blanks as well as particularly stable, form-fitting sleeves for the optimum presentation of your products

- The SetLine allows flexible processing of individual products or sets in defined pack formats - with short set-up/changeover times

- The high-quality, stable construction ensures a long service life with low maintenance requirements

Technical data

- Product:

FS Cups: 68 - 95 mm

FFS Cups: sets of 2, 4, 6, 8, single cups

Bottles: 40 -60 mm - Capacity:

FS cups: 40,000 cups/h

FFS cups: 43,000 cups/h

Bottles: 30,000 bottles/h - Number of layers:

FS cups: 1 and 2-ply

FFS cups: 1 and 2-ply

Bottles: 1-ply - max. height:

FS Cups: 140 mm

FFS Cups: 140 mm

Bottles: 140 mm - Cuff design:

FS cups: full cuff / clip

FFS cups: full cuff

Bottles: Full cuff / Head cuff - Tray feed / fabrication:

FS Cups: Integrated or separate

FFS Cups: Integrated or separate

Bottles: Integrated or separate - Control:

FS Cups: Schneider Electric / Allen Bradley

FFS Cups: Schneider Electric / Allen Bradley

Bottles: Schneider Electric / Allen Bradley

Applications

- Sleeving of cups and bottles to form multi-packs

- Inserting single cups and bottles into trays or perforated trays

- Inserting multi-packs into trays

- Repacking of products

- Application of slip-on lids

- Containers: open trays, perforated trays and trays with lids

Options

- Wide range of options and special solutions to cover specific customer requirements

- Integration of the line into a central carton supply or the direct integration of erectors

- Additional requirements, for example the integration of labelling, inspection or reading systems, intelligent palletising or other downstream equipment can be taken into account

- Efficient processing of required formats with minimum changeover time due to variable configuration

A+F sleeving machines

Sleeving machines

Cup-Sleeving machine SetLine Mini

Produce multi-packs quickly and reliably – with A+F SetLine Mini, our modular solution for free-standing integration into your overall system. You are looking for a low-cost and centrally controlled system? Then this sleeving machine can offer you the ideal mix of small footprint, flexible adaptation to your applications as well as fast retooling times thanks to largely omitting change parts. We deliver the packaging machine to you ready for connection to the electrical and pneumatic supply, equipped with a Nordson hot melt unit and featuring reliable Festo components.

By the way: You can also run the A+F SetLine Mini using a Rockwell control as an alternative to the Schneider Electric PackDrive 3. We would be happy to advise you on this point.

Cup-Sleeving machine SetLine Mini in detail

Benefits

- Cost-effective: as only 2 combination modules (handling modules) are installed

- Modular system concept: allows adaptation to customer-specific applications

- Low space requirement: due to the compact design

- Central machine operation

- Fast changeover times: due to the extensive elimination of interchangeable parts

Technical data

- Performance: 8.000 cups / h

- Products: Becher, Flaschen, Gläser

- Multi-Packs: 1×1, 1×3, 1×4, Einlagig

- Cases: open cases, compartment trays

- electrical connection: 230/400V, 50 Hz, approx. 22 KVA

- compressed air connection: R1″, 6 bar

- machine dimensions: ca. 4.300 x 1.800 x 2.700 (LxWxH)

Applications

- Sleeving of cups and bottles to multi-pack

- Packing of individual cups ans bottles into trays and cases

- Packing of multi-packs into cases

- Commissioning of mixed sets

- Application of cup-lids

- Type of Final Packaging: Open cases, compartment trays, trays / Cases with separate lids

Options

- SetLineMini offers the opportunity to handle with different requirements: labellers, coding units, detection devices, bar code Readers, etc.