Cardboard instead of plastic

The British company, Premier Foods, accomplishes an innovative packaging and palletising solution for dessert cups

No longer wanting to sell its dessert cups in shrink-wrapped plastic trays, the British company, Premier Foods, decided to invest in a combined packaging and palletising centre. Here the cups are now packed in cardboard cases using tray erectors and sleeving machines and then palletised fully automatically. The palletising centre simultaneously handles two additional packaging lines. The entire plant was successfully approved in February 2022. Read on for a more detailed portrait.

As one of the largest listed food companies in the UK, Premier Foods employs a workforce of over 4,000 people at 15 production sites and different branches across the UK. Some 96 percent of the products are made in the UK. The raw materials are supplied to the maximum possible extent by British merchants and farmers.

In the used palletisers the changeover of pallet type takes place via stored product settings. This is also the case with the layer pattern.

In the used palletisers the changeover of pallet type takes place via stored product settings. This is also the case with the layer pattern.

Rice pudding, other puddings and desserts

The brand portfolio of Premier Foods is divided into four main categories, these being: flavours and seasonings; sauces and accompaniments; convenience foods, snacks and soups; and lastly aseptically packaged desserts. In addition, the corporate group makes products such as cakes and desserts to order for many food retailers in the UK.

At the Ambrosia Creamery, Premier Foods makes the UK’s most popular rice pudding and pudding desserts, as well as a host of other desserts. The company itself dates back to 1917. The production site is located in the village of Lifton, in the heart of the county of Devon in southwest England.

Goal was a state-of-the-art multipack format

The first packaging line from A+F went into operation at the Lifton site back in 2012. Since then, a number of other projects have been completed in joint cooperation, the last of which was at the beginning of 2022. “The most recent collaboration was for the development of a state-of-the-art multipack format for our popular dessert cups. In this project we wanted to simultaneously change over to a more sustainable case solution,” comments Graeme Strike, project manager at Ambrosia. At that time, the filled cups were being inserted into an open plastic tray that was additionally wrapped in shrink film prior to palletising. “Now we pack our cups in solid cardboard sleeves and corrugated cardboard cases,” Strike adds.

In addition to this challenge, a suitable plant layout had to be determined in order to be able to spatially incorporate the planned palletising centre with integrated packaging unit in the respective hall intended for this purpose. Furthermore, all existing options from cup filler to product routing were to be maintained. This is where flexibility in the packaging unit design, with its tray erector and sleeving machine, was hugely important. Because this would ensure that the cups could leave the filling line in the existing format and still be processed in a seamless manner by the new packaging and palletising line“, Strike explains.

Successful award of contract after an extensive tendering process

The first stage in choosing a machine was an elaborate tender process. Strike recalls: “It was here that the tray erector and sleeving machine stood out from the rest as well-established and proven flexible machines.“ And there was a further additional advantage over the competitors: the existing equipment could be adapted to the new conditions without any difficulty whatsoever. Choosing one of the other bidders would have necessitated an investment by Premier Foods in replacements. “So the final decision was relatively easy for us”, Graeme Strike continues.

The SetLine sleeves up to 304 dessert cups per minute.

The SetLine sleeves up to 304 dessert cups per minute.

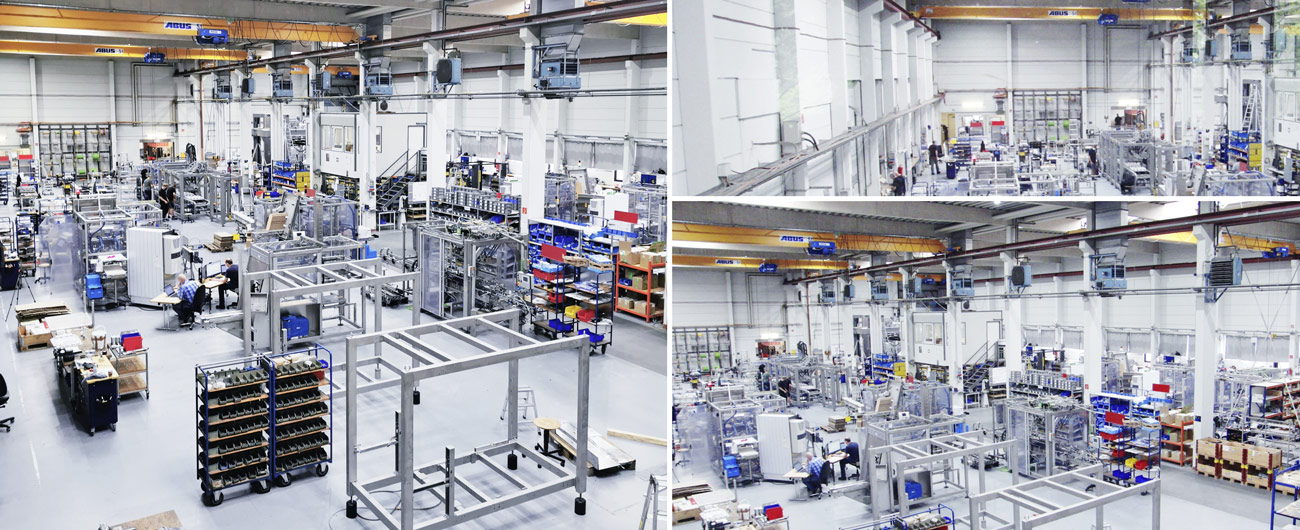

The contract included the layout, two new palletisers, the conversion of an existing palletiser, a multi-former tray erector and a SetLine sleeving machine, also all required conveyors as well as the mechanical-side and control-side connection to the specified interfaces. Two spiral conveyors were purchased and integrated by the general contractor. Equipment from third parties was also taken over, such as X-ray-checkweighers, Inkjet printers, pallet wrappers as well as pallet and case labellers.

During the plant planning, particular attention was paid to ensuring the most energy-efficient operation possible – one of the goals being to minimise the use of expensive pneumatics. Consequently, the most up-to-date servo drives and three-phase drives are used, and vacuum pumps replace conventional Venturi vacuum generators. The entire project was managed on a turnkey basis, including the dismantling and training of operating staff.

Specified output reached in record-breaking time

Assembly work in Lifton started at the end of 2021. The new packaging and palletising centre reached the specified output in record-breaking time. Acceptance was successfully completed in February 2022, just a few weeks after the commissioning. “This was also made possible thanks to the excellent operator training”, Strike emphasises. Another useful tool in this respect was, of course, the “digital twin”. This system is used in the run-up to an investment to determine via computer simulation how to best implement the task set by the customer in a technically and economically expedient manner. In the Premier Foods project this focused on the design of the pallet transport system. However, the “digital twin” can do a lot more than just computer simulation. The tool runs the exact PLC that is to be used by the customer, and this in turn controls the simulation. The knowledge gained in these tests, that are run under close-on operation conditions, helps optimise the machine design as well as the subsequent commissioning at the customer’s premises.

The tray erector, type MultiFormer, automatically forms the desired packs comprising sleeve and wraparound tray.

The tray erector, type MultiFormer, automatically forms the desired packs comprising sleeve and wraparound tray.

Designed for 24/7/365

Since then, the packaging and palletising centre has proven its worth under tough day-to-day working conditions. The plant is designed for 24/7/365. It is currently being used in a two-shift operation. The sleeving machine forms the packaging variants: 2 cups x 1 layer = 2 cups, 2 cups x 2 layers = 4 cups as well as 3 cups x 2 layers = 6 cups. The rated output is 304 cups per minute. The tray erector subsequently forms the desired packs comprising sleeve and wraparound tray. Its rated output is 19.0 packs per minute for the 2-cup sleeves and 12.7 packs per minute for the 3-cup sleeves. The palletiser of the new packaging system also has a rated output of 19.0 packs per minute. The other two palletisers simultaneously handle two other packaging lines. Their rated output is 13.9 packs per minute respectively. On all three palletisers Chep or Euro pallets are used. The changeover of pallet types is carried out - as with the layer pattern changeover - using stored product settings.

“Something we can all be proud of“

“We were well aware of the company’s potential and that of its components“, says Strike. This was an important aspect, considering that the general conditions were far more challenging this time - the project had to be carried out under the difficult circumstances of the UK having left the EU and the Covid pandemic. Among other things, the installation teams had to go into quarantine. Summing things up Strike concludes: “Despite these unprecedented challenges, the A+F team were always closely engaged with us and extremely cooperative. This was definitely one of the key drivers in getting the project done within the budget and on time. And that is something we can all be proud of.”