Handling cups, trays and cases

Wernsing Feinkost invests in an innovative packing unit - for packing, erecting and stacking

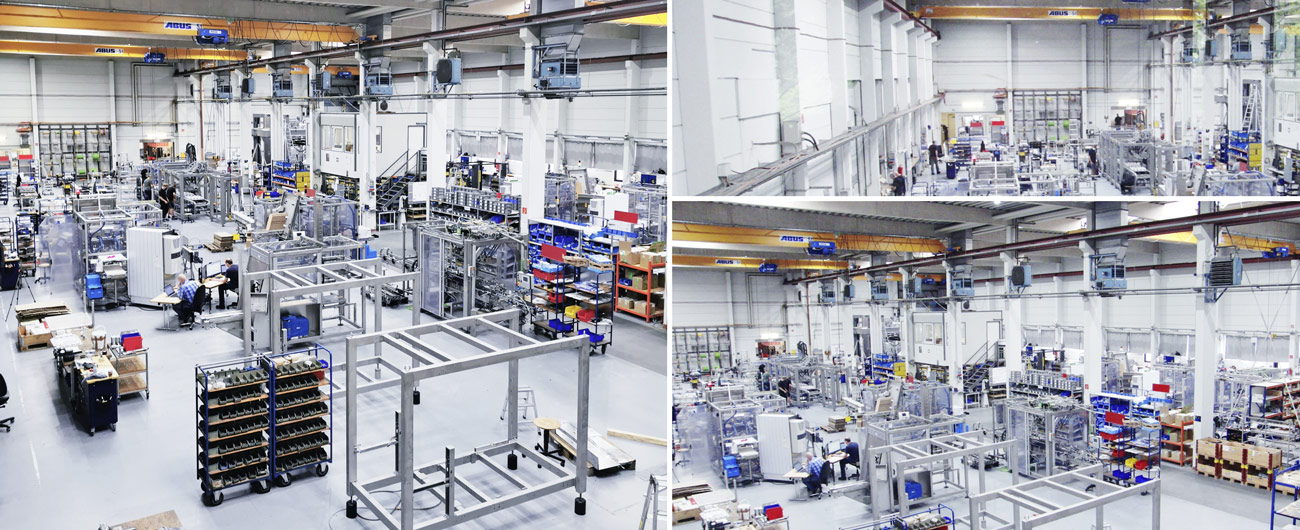

At Wernsing Feinkost GmbH a new plant was put into operation last year which fully automatically places cup-filled products into cases or trays. This solution combines the actual packer with a carton erector and a stacking unit. This compact packing unit has been integrated into an existing line and has a rated output of 150 cups per hour. Read on for a portrait of the company.

The history of Wernsing goes back to 1962, in Addrup-Essen/Oldenburg, in the state of Lower Saxony, when a production facility for French fries was founded. Heinrich Wernsing, then 28, laid the foundation for an exceptional success story. Over the years this small family business has become a modern and dynamic company which is still held in sole proprietorship.

The new packing cell at Wernsing Feinkost GmbH has a rated output of 150 cups per hour.

The new packing cell at Wernsing Feinkost GmbH has a rated output of 150 cups per hour.

Annual sales of over one billion euros

Today, Wernsing Feinkost GmbH is part of the Wernsing Food Family that generates annual sales of over one billion euros at eight production sites in Germany, and at other facilities in Belgium, Denmark, the Netherlands, Poland, Sweden and Spain. In total, this European family of companies employs more than 4,000 people. The site at Addrup alone has more than 1,150 employees, making Wernsing Feinkost GmbH one of the most important employers in the region.

The company group boasts a wide range of products and continues to grow steadily. The portfolio covers potato products as well as antipasti products, spreads, desserts, dressings, dips and sauces, marinades, pasta and savoury products, salads and also soups and stews. In addition to this product range, the services offered by Wernsing, such as the development of individual recipes or repacking, are also much in demand by wholesalers, food retailers and discounters, as well as industrial partners in Germany, in many European countries and around the world.

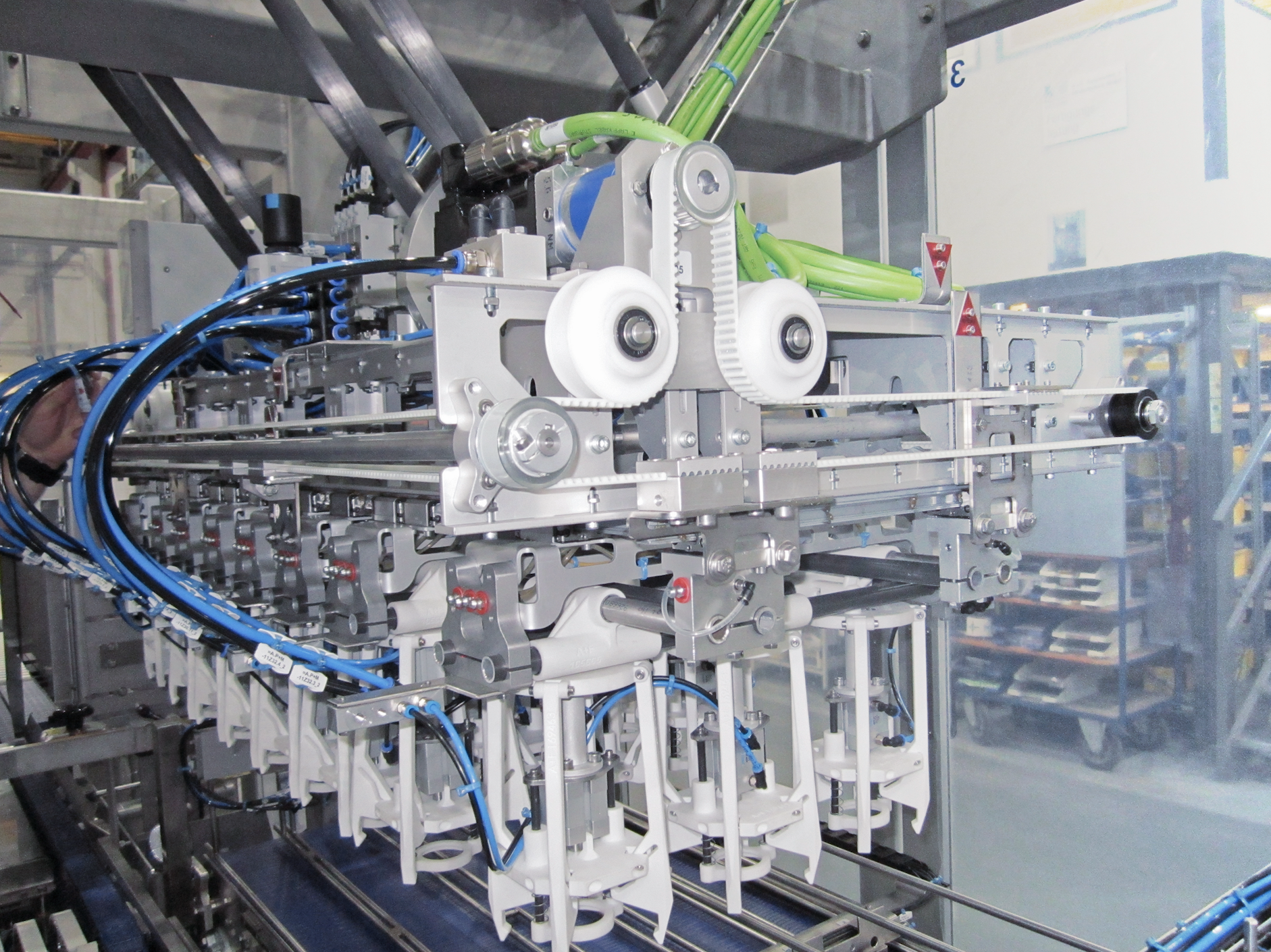

The cup packer is based on the proven Twin-Line basic design, which is individually adapted to each customer's specific requirements.

The cup packer is based on the proven Twin-Line basic design, which is individually adapted to each customer's specific requirements.

Challenging plant layout

In order to be able to keep up with this high level of diversity and the constant growth on the production and packaging side Wernsing is committed to ongoing investments in state-of-the-art plant technology. This is where, for more than two decades now, A+F Automation + Fördertechnik GmbH has been a key partner. The last joint project was in 2021 when an A+F cup packer system was replaced at the Addrup site. The need to invest in a replacement was due to the advanced age of the system and the planned expansion in the production to include yet another packing concept. The corresponding adaptation of several line components also led to an increase in the hourly output.

The gripper fingers were made of plastic using 3D printing. This process offers many advantages compared to milling out the fingers.

The gripper fingers were made of plastic using 3D printing. This process offers many advantages compared to milling out the fingers.

The contract was awarded in August 2020. In detail, the project comprised the plant layout, the packing unit as well as the necessary conveyors and buffer sections. The job was carried out on a turnkey basis. Wernsing was responsible for on-site work by others, such as the dismantling of the old plant, for example. The design of the optimal plant layout proved to be a particularly challenging task. This was due to the very limited available space which was restricted further by numerous existing columns. In addition to this, strict adherence to the interfaces specified by Wernsing was required, and on top of this, Covid-19 measures such as the wearing of masks, keeping a distance, disinfection and testing had to be observed as well.

Gripper fingers produced by the 3-D printer

For the machine, Wernsing decided in favour of the innovative Twin-Line Cup Packer. This is based on a proven basic design that is individually adapted to the customer’s specific requirements. Basically, the Twin-Line packer is a packing unit with two conveyor streams. The one conveyor infeeds a case, carton or tray. The second conveyor is for the infeed of the product. Both streams can be designed to run parallel, but they can also run in opposing directions, feature a single-lane or a multi-lane design. Another option is to use a bar chain. The incoming cups are then picked up according to the packing pattern and placed in the carton.

The bucket packer was combined with a tray erector in the infeed.

The bucket packer was combined with a tray erector in the infeed.

The pick-and-place system is always individually adapted to the product. At Wernsing, the product is grabbed, for example, and not sucked up. The required mechanical grippers for this purpose comprise a rectangular plate with four mobile fingers positioned at the corners. These fingers have to feature a geometry that exactly matches the cup to be picked up. To this end, the fingers are made of plastic using the 3-D printer process. This is much more accurate than cutting out the fingers in a milling process. The plastic material for this purpose is also extremely durable and boasts minimal wear.

The gripper is moved by a so-called handling module that is driven by servomotors. In this way, the mounting plate for the respective grippers can always be positioned precisely by the control system. Wernsing uses two different types of grippers for the required pack formats. These can be replaced by means of quick-release couplings, thus ensuring fast format changes. In addition, special format part carriages make it possible to keep all relevant parts neatly arranged near the respective machine.

2 x 3 or 3 x 3 cups either in single or double layers

For Wernsing, the Twin-Line Packer was combined with a carton erector in the infeed and a stacking unit in the outfeed. In addition, a labeller provided by the customer was also integrated in the infeed. All components were delivered as from 27.02.2021, these were then set up and electrically connected by 03.03.21. The commissioning began on 02.03. The acceptance took place on 12.03.21 already. During the actual packing process the cups are fed in on the customer’s side in a single lane. The Twin-Line Packer also takes up the cups in a single lane and then, depending on the pack format, distributes the cups over three or four lanes in the infeed. The actual pack formats for the plant are 2 x 3 or 3 x 3 cups, either in a single layer or in a double layer. The previously erected cases or trays reach the packing plant at the same time via the second conveyor belt. Once positioned under the handling module with the appropriate gripper, the module inserts the cups assembled to the selected pack format. With the pack format 2 x 3 always two cartons are filled at the same time in order to achieve the required output per hour. In this case, the infeed of the cups is on four lanes. The pack format 3 x 3, on the other hand, is formed on three lanes. The filled packs then move into the stacking unit. Here stacks of packs are formed depending on the palletising pattern of the customer’s loader. Stacks with two or three layers are possible. The case or the tray can, however, also be fed directly to the final palletising system. The achievable rated outputs are listed in Table 1. The packer itself is designed for a rated output of 150 cups per minute.

Condition Monitoring as a useful tool

All plant components are designed to allow a smooth subsequent conversion or expansion within the given structural limits. For example, Wernsing also offers a cup with a lid size of 130 x 130 mm, that can be processed by the Twin-Line Packer at a later date, as required. To put this in perspective: the size of the cups is currently approx. 114 x 114 mm. And speaking of the future: In this connection, Wernsing also decided in favour of using the Condition Monitoring tool. Condition Monitoring is used to automatically record extensive data relating to the production, machine and the environment. This applies, among other things to status messages, warnings and malfunctions of the machine as well as production data. All of these data are stored on a stand-alone industrial PC, archived and displayed on a dashboard that can be accessed using any up-to-date browser. The architecture can thus be integrated in a company network without requiring additional hardware. This tool is particularly interesting for maintenance purposes as any required measures, such as the replacement of a bearing, can be detected in advance, as a preventive measure. Through the achieved transparency it also offers Wernsing the opportunity to optimise and secure the plant’s performance. In short: output, flexibility and reliability are three absolute key factors behind the Wernsing success model, and these are realised 100 percent with the new Twin-Line solution, also with a view to the future.

Read the full article as an online pdf. Published in LVT Lebensmittel Industrie, copy 5-6/2022.