Tricky conditions: an inclined area, fluctuating dimensions, irregular orientation

The Sachsenmilch dairy automates its cheese wedge packaging using a Flexpicker

Sachsenmilch Leppersdorf GmbH is one of Europe’s most modern dairies and one of the largest investment projects in the history of the Theo Müller Group. Over one billion euro has been invested in the new development and in expansion projects since the takeover. A further investment was successfully concluded at the beginning of 2021. The goal was to automate the previously manual packing of cheese wedges.

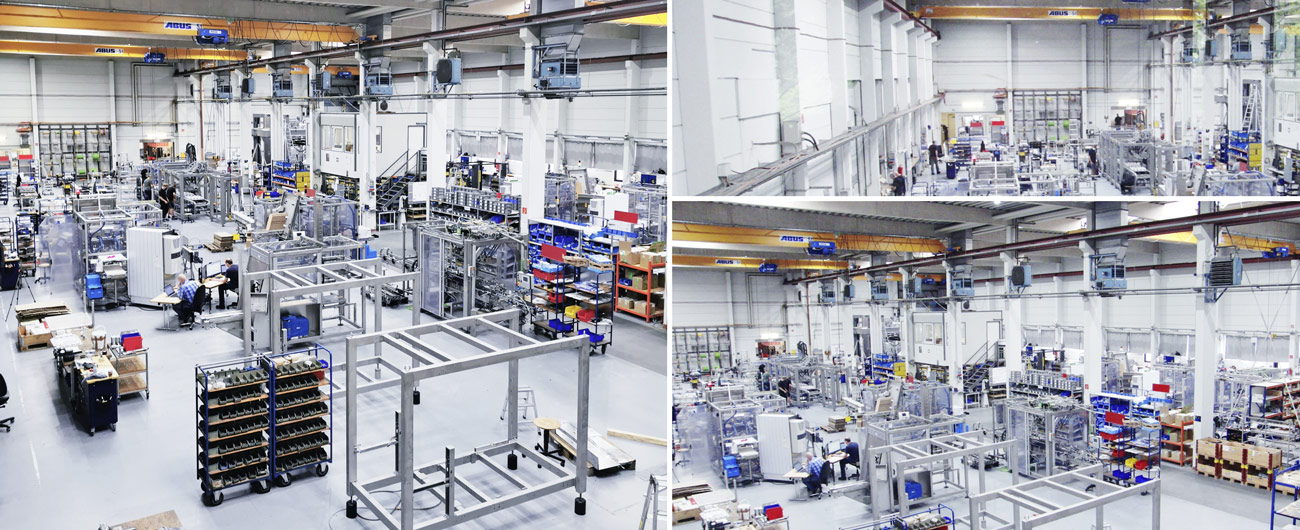

With some 2,800 employees Sachsenmilch processes around 1.8 billion kilogrammes of raw milk a year into a wide range of products that, besides milk, butter, yogurt and cheese, also includes whey derivatives for baby food as well as bioethanol. The food products are sold under the brand names Sachsenmilch, Müller und Loose, among others.

An impressive sight: with some 2,800 employees Sachsenmilch processes around 1.8 billion kilogrammes of raw milk a year into a wide range of products.

An impressive sight: with some 2,800 employees Sachsenmilch processes around 1.8 billion kilogrammes of raw milk a year into a wide range of products.

Cheese wedges vary in size significantly

About half of the raw milk supplied is processed into cheese and packed in packaging variants to meet the customer demand. Sachsenmilch’s 450 g cheese wedges, which are machine cut from cheese wheels of approx. 12 kg according to a defined pattern, play an important role in this process. The square-shaped middle cut which produces three wedges, is always identical. These sections can always be identified in that they only feature two sides of rind and not three, as is the case in the wedges cut from the edge. The size of the middle wedge is always the same, whereas that of the outer wedges varies significantly. The reason for this is as follows: although all cheese wheels have approximately the same weight, they vary in diameter and height due to the maturing process. If the diameter of the wheel is smaller, for instance, then the edge wedge is shorter and wider, whereas with a larger diameter the segment is longer and thinner.

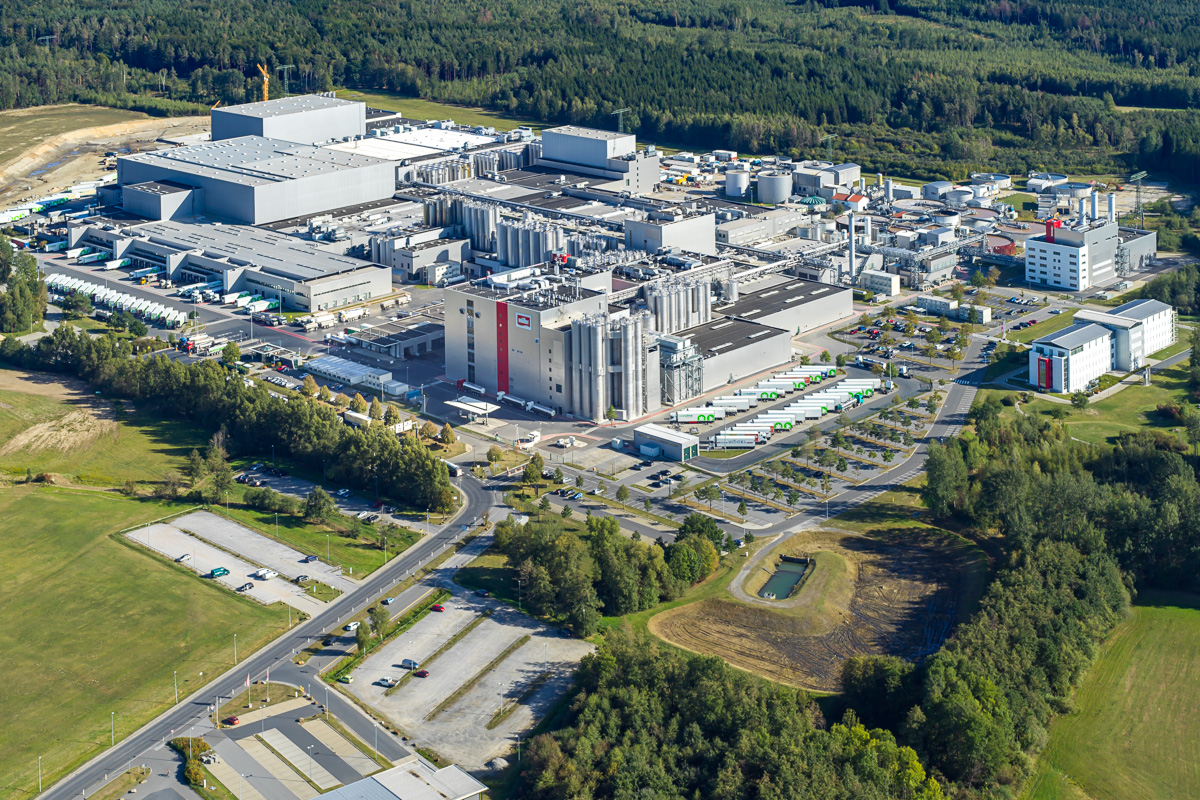

The compact and high-performance Flexpicker with integrated cartoner

At Sachsenmilch the cheese wedges have until now been put into shipping cartons manually. “This type of work has great potential for automation. We were therefore looking for a solution that would enable an efficient mechanical packing of the cheese wedges,“ recalls Katharina Rossow, Project Engineer for Technical Projects at Sachsenmilch. During the initial planning phase, it was even considered changing the entire cheese wedge production to mechanical processing. “The packer, however, would then be so big that it would exceed the available space at the planned site”, Rossow comments. Sachsenmilch therefore focused on the main cheese type that accounts for approximately two-thirds of the production. The remaining third was to continue with manual insertion into the trays.

“We decided in favour of a cooperation with A+F due to their sound and reliable technology and the positive experience from many joint projects especially regarding the individual customised solution and project implementation “, Rossow points out. The key element of the solution is a so-called Flexpicker with integrated cartoner. This Flexline design combines two proven product groups in one machine frame, both mechanically and regarding the control. The result is first of all a significant synergy effect in the control – one system is all that is needed for both tasks. Secondly, the machine boasts a very compact design which is another bonus, and not just for Sachsenmilch. This is because with existing buildings there is always the challenge of finding a machine that fits into the available space conditions. Rossow emphasises: “This worked out perfectly. Operation and maintenance of the plant can be carried out easily from all sides. The solution simply meets all the requirements originally set out by Sachsenmilch.“

Gripper system, sensor system and condition monitoring make their debut

Unlike the components of the basic machine, the sensor system and the gripper system for the cheese wedge product had to be developed from scratch. “At Sachsenmilch we were not familiar with the chosen technology, but it quickly became our preferred solution. And we were confident that it would do the job”, Rossow adds.

The condition monitoring module also made its debut at Sachsenmilch with this project and was integrated in the Flexline packaging machine. Condition monitoring automatically records comprehensive data on the production, machinery and surrounding area. This also applies to status messages, warnings and faults in the machine as well as to production data. All of these data can be stored and archived on a stand-alone industrial PC and displayed in a dashboard that is accessible via any current browser. The system architecture can thus be integrated in a company network without requiring additional hardware. Rossow: “This tool was a particular requirement of our maintenance department. It also gives us the opportunity to optimize the plant performance thanks to the accomplished transparency. This is really very helpful.”

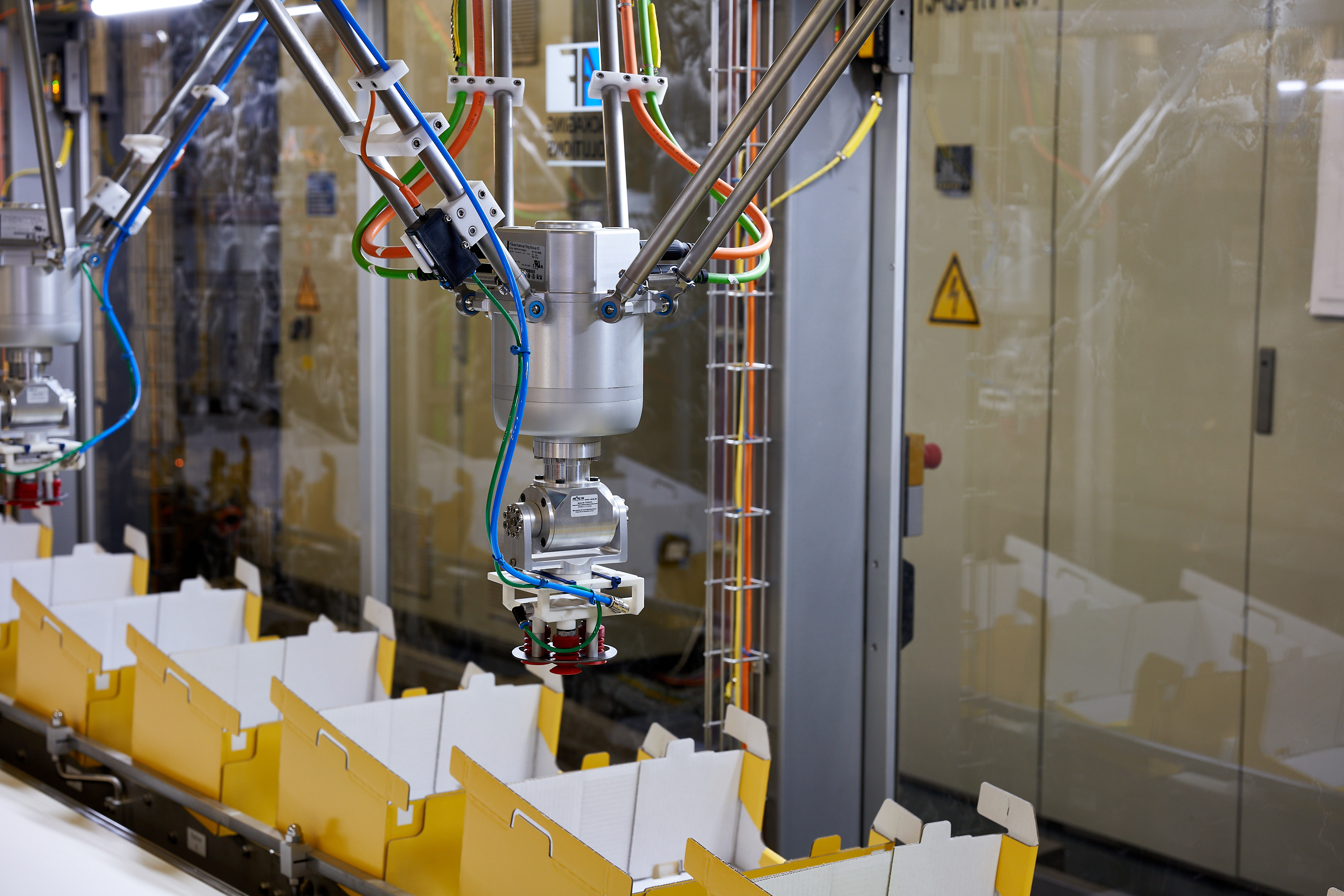

Rapid action unit: a total of four Delta-3 Pickers fill the cartons according to a nested packing scheme in three or four layers.

Rapid action unit: a total of four Delta-3 Pickers fill the cartons according to a nested packing scheme in three or four layers.

Cheese wedges are not aligned upstream of the packer

The entire project was carried out by A+F on a turnkey basis, including the operator training. Besides the Flexline, the order included the mechanical and control-side connection to the cheese cutter, the thermoforming line as well as the remaining manual removal that forms the actual interface. “It had to be implemented in such a way that we could continue using manual removal for the remaining third of our cheese wedges. Operation can therefore take place via manual removal or the machine. Everything is functioning very well”, Katharina Rossow sums up.

The plant components were delivered as planned on 02.02.21. Just one week later the first cheese wedges were passing through the plant. These are conveyed from the remaining manual workstation to the Flexpicker by a product conveyor. Instead of being aligned they are left arranged in a rather “chaotic state”. At the infeed a barcode recognition system checks the cheese wedge from below for the correct product allocation. In addition, the cheese wedges are scanned for any intermediate top film roll changes from the upstream thermoforming line. Cheeses with an incorrect barcode or a detected top film change are discharged.

3-D inspector detects shape, position and orientation

After the inspections the cheese wedges are distributed on two lanes. On both lanes a 3-D inspector records the wedge shape, its position and the orientation of the cheese. This information enables the Delta-3 picker to approach the cheese wedge in the right position, pick it up and place it in the unfolded shoulder tray. The wedge is picked up by a vacuum that is generated using compressed air by means of the Venturi effect, similar to a water jet pump. This allows the suction head a freedom of movement that would not be possible with a vacuum pump.

Identical control for basic machine and robot arm

The actual Delta-3 Picker is a servo-driven robot arm which besides the x, y and z axes has a rotary axis and a tilting axis. In this way it can move to any position in its operating range. Both the basic machine and the robot arm have an identical control system which is beneficial for the customer regarding operation and maintenance.

The wedges passing the first picker, which are within the respective movement radius but cannot be detected in the time window, are then processed by the second of all in all four pickers. The wedges not picked up by the second picker are then picked up by the third picker and those not picked up by the third picker are finally picked up by the fourth picker. If a cheese wedge cannot be picked up due to drawn in secondary air, it is discharged via a chute into a discharge box downstream of the fourth picker.

Satisfied in every respect: “The solution simply corresponds to all the requirements set out by Sachsenmilch“, says Katharina Rossow, Project Engineer for Technical Projects at Sachsenmilch.

Satisfied in every respect: “The solution simply corresponds to all the requirements set out by Sachsenmilch“, says Katharina Rossow, Project Engineer for Technical Projects at Sachsenmilch.

“We at Sachsenmilch are very satisfied with the implemented job“

The carton erector integrated in the plant with a folding station as special version doubles the cardboard at the front access to the product parallel to the packing process. The ready-sealed cartons are placed on an inclined carton conveyor. The control cycles these cartons corresponding to the filling level in the infeed. The carton stream and the cheese wedge stream flow in opposite directions. Each of the four pickers has access to two cartons. If, for example, one of the cartons is filled and moves to the shoulder closer, this design allows the picker to continue feeding the second empty carton. If, on the other hand, a carton that is not completely filled moves on one position further, the cheese wedges are packed into this carton by the next picker. By way of a counting function, the pickers know exactly how many cheese wedges still need to be inserted into the respective carton.

In this way, the four Delta 3 pickers fill the cartons in three or four layers according to a nested packing scheme. The shoulders are then closed on the filled carton before it is moved to the take-off roller conveyor for manual removal. There are two operators on duty per shift to ensure a safe and reliable operation of the automatic cheese wedge packaging. “We have now gained so much potential that we can mechanically pack our maximum cutting capacity”, Rossow comments. Does this positive outlook also mean an equally positive conclusion for the project? Absolutely, Katharina Rossow stresses: “Everything was carried out according to schedule and within budget. Putting it in a nutshell: At Sachsenmilch we are very satisfied with the job done, both on the production and on the maintenance side.“

You want to read more? Find here the full report as a download.

Published in: International DAIRY magazine, December 2021